In sewage treatment plants, screening and straining are fundamental processes for managing wastewater effectively. These processes play crucial roles in separating debris and solid materials from the water before it undergoes further treatment. Here’s a detailed look at how screening and straining work, their benefits, and their applications.

Screening in Sewage Treatment

What is Screening?

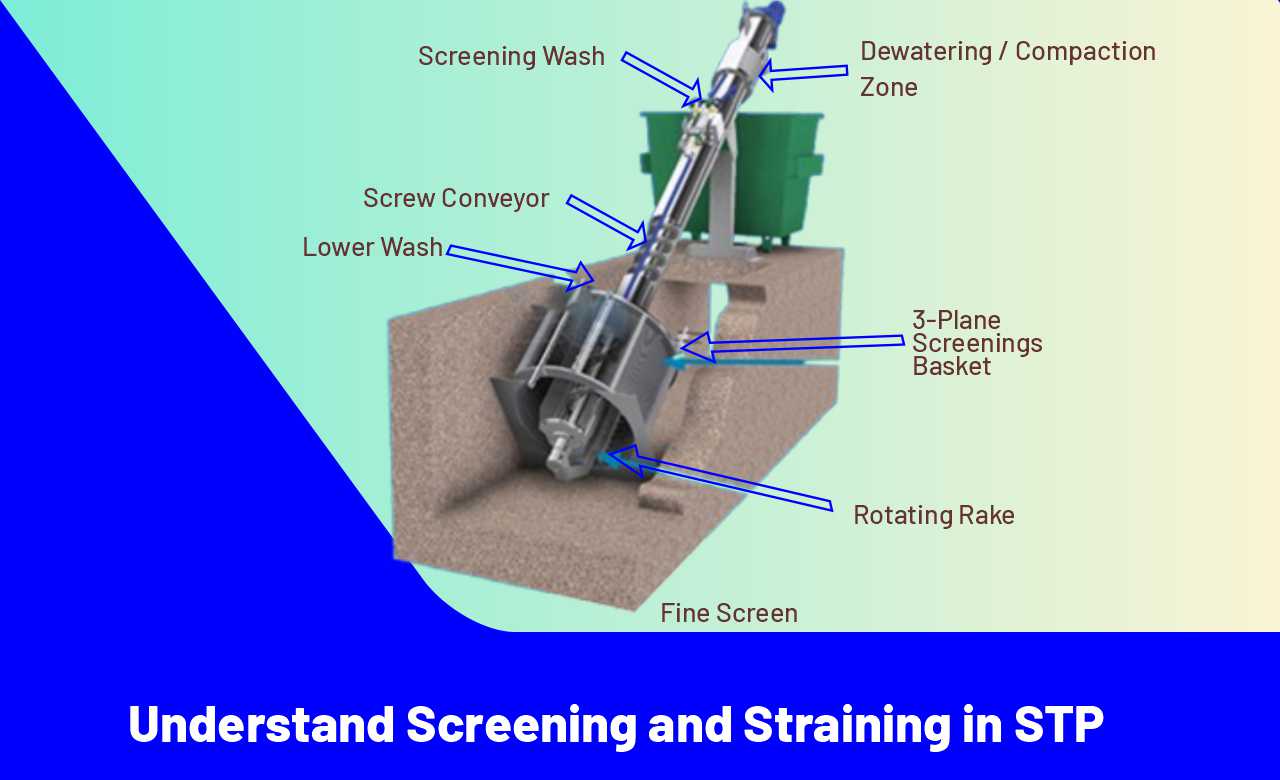

Screening is the initial stage in wastewater treatment that involves the removal of larger particles from the sewage flow. This process uses various types of screens to filter out materials such as domestic waste, feces, toilet paper, and mineral solids. The effectiveness of screening is determined by the screen’s mesh size and the type of sewer system in place.

Types of Screens

- Bar Screens: These screens have vertical bars that capture large debris while allowing wastewater to pass through.

- Fine Screens: With smaller mesh sizes, fine screens are used to remove smaller particles and finer debris.

- Rotary Screens: These cylindrical screens rotate to continuously filter out debris.

Benefits of Screening

- Improved Treatment Efficiency: By removing large particles, screens help prevent damage and clogging of subsequent treatment equipment.

- Enhanced Dewatering: Screens, particularly when combined with wash presses, significantly reduce the water content in the captured debris, leading to more efficient dewatering.

- Reduced Disposal Costs: By compacting and washing the screenings, the volume and weight of the waste are reduced, lowering disposal expenses.

Screening Process

- Collection: As wastewater flows through the screen, larger particles are captured.

- Washing: A wash press cleans the debris, removing organic matter and preparing it for further handling.

- Compaction: The cleaned debris is compacted to reduce its volume and facilitate easier disposal.

Applications

Screening is commonly used at the inlet of central treatment facilities and is suitable for both urban and rural settings. It is particularly effective at surface water inlets, where it prevents debris such as leaves, algae, and plastic waste from entering subsequent treatment stages.

Straining in Sewage Treatment

What is Straining?

Straining is a basic filtration method used to remove suspended silt and solids from water by passing it through a piece of cloth or mesh. While straining is not a comprehensive treatment solution, it is effective in reducing turbidity and improving water quality to a certain extent.

Benefits of Straining

- Cost-Effective: Straining is a simple and inexpensive method for removing larger particles from water.

- Time-Efficient: The process is quick and requires minimal time to implement.

- Improved Water Quality: Straining lowers turbidity and can reduce the risk of waterborne diseases like cholera when used as a preliminary treatment step.

Straining Process

- Filtration: Water is passed through a cloth or mesh to filter out suspended solids.

- Maintenance: The cloth or mesh must be kept clean to avoid introducing additional contaminants into the water.

Applications

Straining is particularly useful in small-scale applications, such as home use or community-level water treatment. It is effective with surface water sources and can serve as an initial step before more advanced treatment processes.

Maintenance and Operation

Screens

- Construction: Screens are typically made from steel grids or larger sheets of screening material. They may be straight or cylindrical, with various mesh sizes depending on the application.

- Operation: Straight screens can be manually cleaned, while cylindrical or drum screens require mechanical cleaning and backwashing.

- Maintenance: Regular cleaning and debris removal are necessary to ensure optimal performance. Training may be required for effective debris management.

Strainers

- Construction: Strainers are simple devices often made from cloth or mesh.

- Operation: They require periodic cleaning to maintain effectiveness and prevent additional contamination.

- Maintenance: Regular inspection and cleaning of the straining material are essential to ensure continued performance.

Conclusion

Screening and straining are essential processes in wastewater treatment, each serving distinct roles in managing debris and solids. Screening effectively removes larger particles and prepares wastewater for further treatment, while straining provides a basic filtration solution.

Both methods are critical in ensuring that water is adequately prepared for advanced treatment stages, reducing overall treatment costs, and improving water quality. For more information and tailored solutions, contact 3D Aqua.

By understanding and implementing these processes, wastewater treatment facilities can enhance their operational efficiency and contribute to more sustainable water management practices.

Hello There. I found your blog using msn. This is a very

well written article. I will make sure to bookmark it and come

back to read more of your useful information. Thanks for the post.

I’ll certainly comeback.