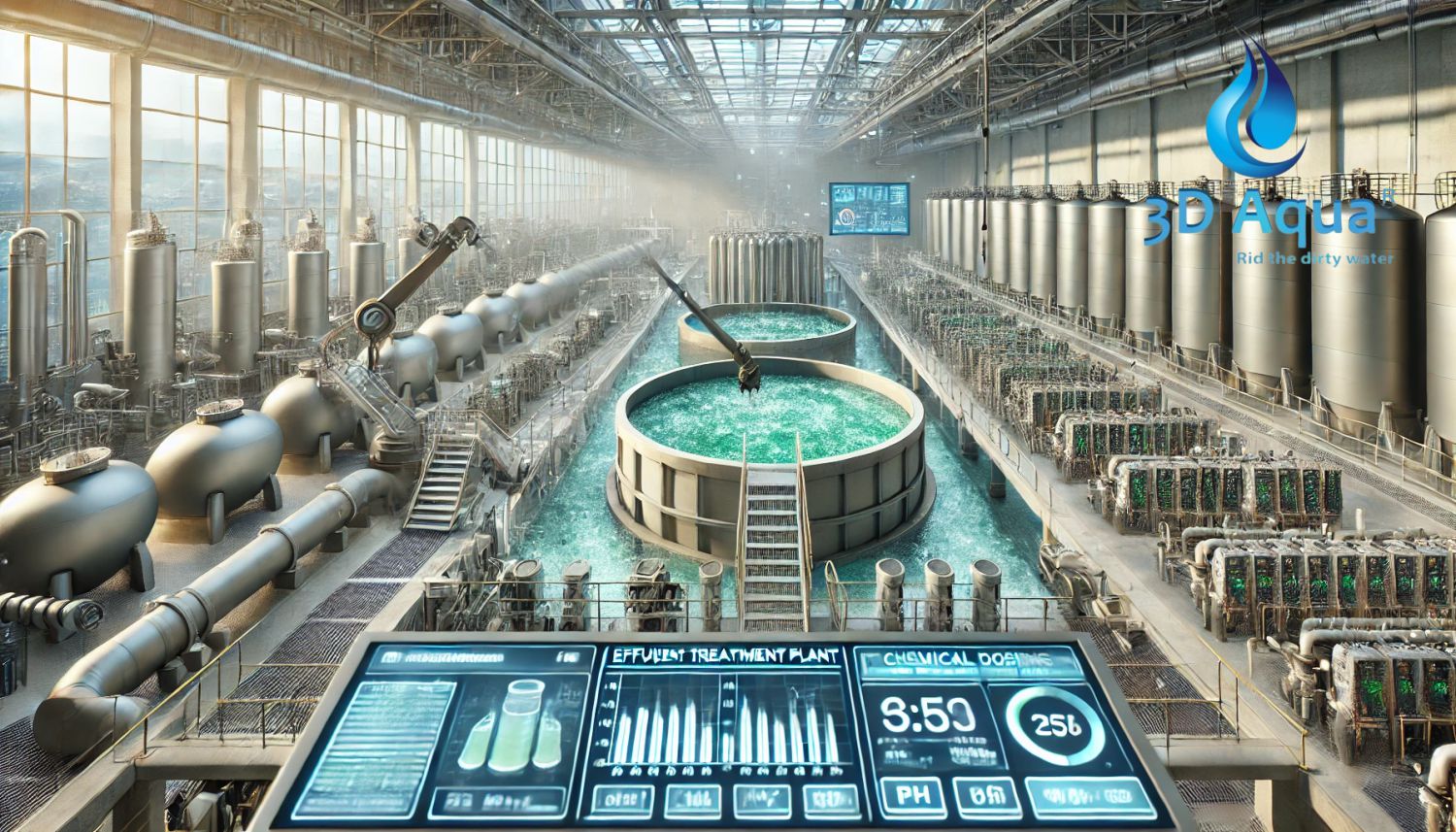

Effluent Treatment Plants (ETPs) play a crucial role in ensuring that industrial wastewater is treated effectively before being released into the environment. One of the most vital aspects of ETP operations is chemical dosing, which directly influences the efficiency and effectiveness of the treatment process. Proper chemical dosing ensures optimal pollutant removal, enhances system performance, and helps maintain compliance with environmental regulations. However, incorrect dosing can lead to inefficiencies, increased operational costs, and potential regulatory violations.

This article delves into how chemical dosing impacts ETP performance by examining dosing methods, chemical selection, timing considerations, and monitoring systems. By understanding these key elements, plant operators, engineers, and environmental professionals can optimize their ETP operations for better wastewater treatment outcomes.

The Science Behind Chemical Dosing in ETPs

Chemical dosing serves as the foundation of wastewater treatment by initiating reactions that transform pollutants into removable forms. The process begins when carefully selected chemicals are introduced into the wastewater stream at specific stages. These chemicals help separate contaminants from water, facilitating their removal during different treatment phases.

Key Treatment Stages and Their Chemical Requirements

1. Primary Treatment Chemicals

The first stage of wastewater treatment involves the removal of suspended solids and other large particles. The primary chemicals used in this phase include:

- Coagulants: These destabilize suspended particles and make them clump together. Common coagulants include aluminum sulfate (alum), ferric chloride, and polyaluminum chloride (PAC). The required dosage varies based on factors such as wastewater composition, pH levels, and turbidity.

- Flocculants: These aid in forming larger, heavier particles that can be easily separated from the wastewater. Typical flocculants include synthetic polymers and natural compounds like starch-based coagulants.

2. Secondary Treatment Additives

Once primary treatment removes large contaminants, the secondary phase focuses on eliminating dissolved and finer particulate pollutants. This stage often involves biological treatment, where microorganisms break down organic matter. Key chemicals include:

- Polymers: Used to aggregate finer particles into larger, settleable masses, improving sludge separation. However, overdosing can lead to excessive sludge production and operational challenges.

- Biocides: These control microbial growth and prevent unwanted bacterial overgrowth that could disrupt the treatment process.

3. pH Adjustment Chemicals

Maintaining the correct pH level throughout treatment is essential for optimal chemical performance. The choice of pH adjusters depends on whether the wastewater needs to be neutralized, acidified, or alkalized:

- Acids (e.g., sulfuric acid, hydrochloric acid) lower the pH for industries discharging highly alkaline wastewater.

- Bases (e.g., sodium hydroxide, lime) increase pH levels when wastewater is too acidic.

- Buffering agents ensure pH stability and enhance the effectiveness of coagulants and disinfectants.

Optimizing Chemical Usage for Maximum Efficiency

Achieving optimal ETP performance requires careful chemical selection, accurate dosing, and real-time adjustments based on wastewater characteristics. Key considerations include:

1. Comprehensive Wastewater Analysis

Regular testing of wastewater composition helps in determining the correct chemical dosing strategy. Important parameters to monitor include:

- Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD): Indicators of organic pollutants.

- Total Suspended Solids (TSS): Determines the need for coagulants and flocculants.

- Heavy Metal Concentrations: Dictates the need for specialized chemical treatments.

2. Adjusting for Flow Rate Variations

ETPs handle fluctuating wastewater volumes throughout the day. Flow-proportional dosing ensures that chemical inputs match the incoming wastewater volume, preventing overdosing or underdosing. Modern flow meters and proportional dosing pumps can automatically adjust chemical dosing based on real-time flow data.

3. Accounting for Environmental Factors

Seasonal and environmental changes, such as temperature fluctuations and rainfall, can alter wastewater composition. A flexible dosing strategy that accommodates these variations ensures consistent treatment performance.

Modern Chemical Dosing Technologies

Advancements in dosing technology have significantly improved the precision and efficiency of chemical application in ETPs. Some notable innovations include:

1. Automated Dosing Systems

- Real-time monitoring and control: Smart dosing controllers continuously measure wastewater parameters and adjust chemical dosing automatically.

- Prevention of overdosing and chemical wastage: Automated systems ensure accurate chemical delivery, optimizing treatment costs.

2. Digital Monitoring Tools

- Online sensors track multiple parameters such as pH, turbidity, and conductivity in real-time.

- Instant feedback mechanisms allow operators to make immediate dosing adjustments.

- Remote monitoring capabilities enable plant managers to oversee operations even when off-site.

3. Preventive Maintenance Programs

Regular maintenance of chemical dosing systems prevents performance degradation. Routine inspections, calibration of dosing pumps, and cleaning of injection points help maintain dosing accuracy and prolong equipment lifespan.

Enhancing ETP Performance Through Optimized Chemical Dosing

The efficiency of an ETP relies heavily on proper chemical dosing. A well-planned dosing strategy ensures:

- Compliance with environmental discharge regulations

- Reduction in chemical consumption and operational costs

- Longer equipment lifespan due to reduced scaling and corrosion

- Consistent high-quality treated effluent

Take Action for a More Efficient ETP

Optimizing chemical dosing is key to maximizing the performance of your Effluent Treatment Plant. Whether you need assistance in selecting the right chemicals, upgrading to automated dosing systems, or improving operational efficiency, 3D Aqua offers tailored solutions to meet your specific requirements.

📞 Contact Us for Expert Guidance

- Phone: 0120 – 415 3030

- Mobile: 70111 43366, 626262 9090

- Helpline: +91 89630 89630

- Email: info@3daqua.in

- Website: www.3daqua.in

Let us help you enhance your wastewater treatment processes with effective chemical dosing strategies!