In the world of wastewater treatment, every stage in the process plays a critical role in ensuring that sewage is properly treated before it is released into the environment. One of the foundational and often underestimated processes is grit removal. While it might seem like a minor part of the treatment cycle, grit removal is essential to maintaining the long-term efficiency and functionality of any sewage treatment plant (STP).

At 3D Aqua, we understand the impact that grit and inorganic materials can have on a treatment system’s performance. As a leading sewage treatment plant manufacturer, we integrate cutting-edge grit removal technologies into our STP designs to deliver optimal performance, durability, and efficiency. In this article, we’ll explore the importance of grit removal in sewage treatment, the types of grit commonly encountered, the methods used to remove grit, and how 3D Aqua provides best-in-class solutions for this crucial process.

What is Grit in Sewage?

Grit in wastewater typically consists of heavy inorganic materials such as:

- Sand

- Gravel

- Broken glass

- Metallic fragments

- Non-biodegradable debris

- Cinders

- Eggshells

- Coffee grounds

Unlike organic matter, these materials are not decomposed by biological processes in the treatment plant. Grit enters the sewer system through a variety of channels, including:

- Stormwater runoff

- Street cleaning wash water

- Construction site debris

- Industrial discharge

- Soil erosion

If not removed early, grit accumulates and causes multiple operational problems in the sewage treatment plant.

Why is Grit Removal Necessary?

Efficient grit removal offers several key benefits and addresses a range of operational challenges. Let’s explore the major reasons why grit removal is an indispensable process:

1. Protection of Mechanical Equipment

Grit is highly abrasive and can cause significant wear and tear on mechanical components like:

- Pumps

- Valves

- Conveyors

- Clarifiers

When grit isn’t removed at the primary stage, it travels downstream and damages moving parts and pipe interiors, shortening their lifespan. Replacing or repairing these components is costly and time-consuming.

2. Prevention of Pipe and Channel Clogging

If grit is allowed to accumulate in pipelines or treatment channels, it can lead to serious clogs and sedimentation. This causes:

- Reduced hydraulic capacity

- Flow disruptions

- Increased pumping energy costs

- Emergency maintenance requirements

Proper grit removal ensures a smooth and uninterrupted flow throughout the STP system.

3. Improved Efficiency of Biological Treatment

Grit can settle in biological tanks and interfere with the growth of essential microorganisms that digest organic waste. The presence of inorganic solids may:

- Displace useful bacteria

- Reduce oxygen transfer

- Decrease overall treatment efficiency

By removing grit, the biological processes operate more effectively and maintain optimal microbial health.

4. Reduced Sludge Volume and Handling Costs

Grit contributes to unnecessary volume in sludge, increasing the burden on sludge treatment units and disposal processes. Removing grit early leads to:

- Lower sludge handling costs

- Improved dewatering efficiency

- Reduced landfill or disposal needs

Techniques for Grit Removal in STPs

Modern sewage treatment plants use a variety of grit removal technologies, each tailored to the specific composition and volume of the incoming wastewater. Here are some of the most widely adopted methods:

1. Horizontal Flow Grit Chambers

This is the most traditional and commonly used grit removal method. Wastewater flows at a reduced velocity through a long rectangular channel, allowing heavy grit particles to settle due to gravity.

- Advantages: Simple design, low maintenance

- Limitations: Ineffective at capturing finer particles; requires regular manual cleaning

2. Vortex Grit Chambers

In this system, wastewater enters a circular tank tangentially, creating a swirling motion. The centrifugal force separates heavier grit particles from lighter organic matter.

- Advantages: Higher removal efficiency; automated grit removal

- Limitations: Slightly more complex design and costlier installation

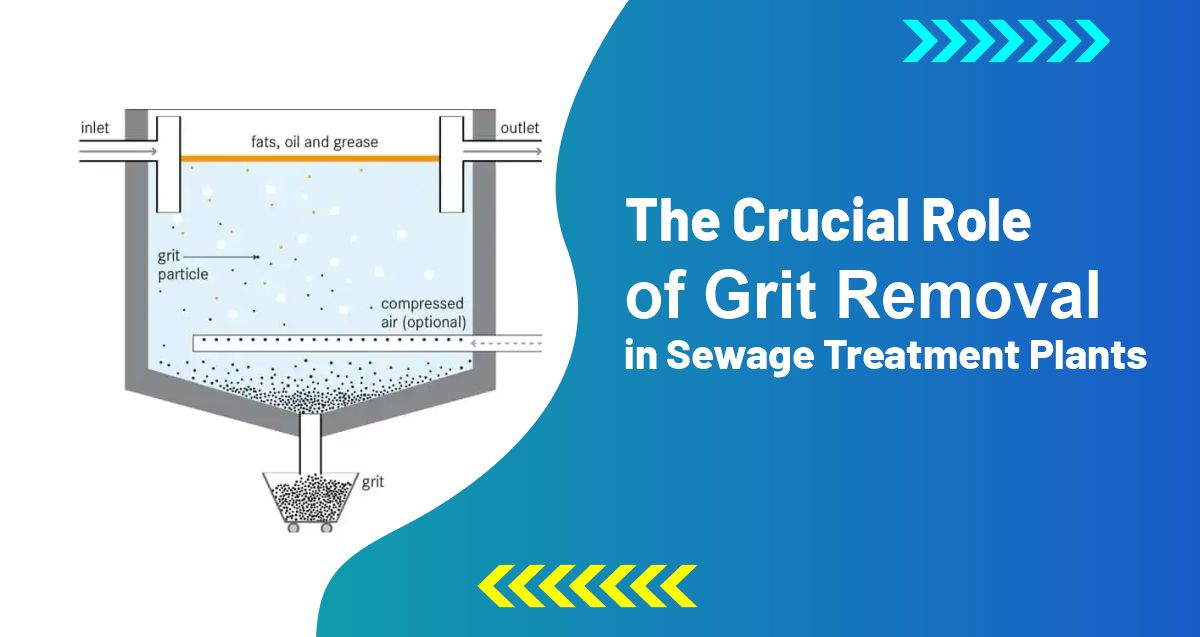

3. Aerated Grit Chambers

Here, air is injected into the chamber, inducing spiral motion in the wastewater. Organic materials remain in suspension, while grit settles and is collected at the bottom.

- Advantages: Effective separation; good for combined sewer systems

- Limitations: Requires aeration equipment and more energy

4. Cyclonic (Hydrocyclone) Separators

These units use high-velocity water flow to create centrifugal force within a conical chamber. Grit is forced to the outer wall and settles at the bottom.

- Advantages: Compact design; efficient grit capture

- Limitations: Best suited for high-flow STPs

Each of these techniques has its advantages and is chosen based on the plant’s capacity, budget, wastewater characteristics, and maintenance preferences.

How 3D Aqua Delivers Excellence in Grit Removal

At 3D Aqua, we design and manufacture STP systems that include highly efficient grit removal mechanisms. Our goal is to reduce maintenance costs, prolong equipment life, and increase treatment efficiency for every client. Here’s how we ensure superior grit management in our solutions:

✔ Tailored System Design

We don’t believe in one-size-fits-all. Every sewage treatment project is different. Our engineering team works closely with clients to analyze grit load, wastewater characteristics, and site-specific requirements to build custom grit removal units.

✔ Advanced Mechanical Integration

We equip our grit chambers with:

- Automatic grit scrapers

- Screw conveyors

- Grit washing units These systems ensure consistent removal, cleaning, and disposal of grit, reducing manual labor and improving hygiene at the facility.

✔ Durable and Corrosion-Resistant Materials

Our grit chambers and separators are made from high-quality stainless steel or reinforced concrete, designed to withstand corrosion, abrasion, and harsh wastewater environments. This ensures long-lasting performance with minimal wear.

✔ Energy-Efficient Operation

3D Aqua designs all its systems to operate with minimal energy input. From optimized air blowers in aerated grit chambers to low-friction mechanical components, our equipment helps reduce your plant’s carbon footprint.

✔ Easy Maintenance and Monitoring

We provide automation-ready grit removal systems that include:

- SCADA integration

- Real-time monitoring sensors

- Self-cleaning mechanisms

These technologies reduce operator intervention and ensure consistent grit removal even in fluctuating flow conditions.

Applications of Grit Removal Systems

Grit removal isn’t just for large municipal wastewater treatment plants. It is also vital for:

- Industrial STPs: Industries producing high amounts of sand, ash, or metallic waste need strong grit removal systems.

- Packaged STPs: Even compact systems require grit chambers to protect downstream equipment.

- Stormwater Treatment: During heavy rainfall, street debris and sand enter drains. Grit chambers help prevent overflow and equipment damage.

Why Choose 3D Aqua for Sewage Treatment Plant Solutions?

As a trusted name in wastewater treatment across India, 3D Aqua offers reliable, durable, and efficient grit removal solutions tailored to various industries and municipal setups.

✅ Highlights of Our STP Systems:

- Prefabricated and modular designs

- High-capacity handling (50 LPH to 50,000 LPH)

- On-site installation and training

- Low maintenance and long life

- Compliance with CPCB and NGT standards

Our grit removal systems are integrated into packaged, prefabricated, and conventional STPs alike—ensuring performance at every level.

Conclusion: Grit Removal is the First Line of Defense

Grit removal is not just a preliminary step—it is the foundation of a successful sewage treatment process. By ensuring that inorganic solids are removed at the outset, treatment plants can protect expensive machinery, avoid costly breakdowns, maintain flow rates, and enhance biological treatment efficiency.

At 3D Aqua, we bring industry-leading grit removal technologies that help you get the most out of your STP investment. Whether you’re managing a municipal project, a residential colony, or an industrial facility, we provide tailored systems that keep your plant running at peak efficiency.

Need Help Choosing the Right Grit Removal System?

We’re here to help! Contact 3D Aqua today for personalized consultation and find the best water and wastewater treatment solutions for your needs.

📞 Call Us: +91-6262629090

📧 Email: info@3daqua.in

🌐 Website: www.3daqua.in

Let’s work together toward a cleaner, safer, and more sustainable environment.