Introduction

Dairy industries are among the largest contributors to wastewater in the food and beverage sector. Every stage of milk processing—from pasteurization, cooling, and cheese-making to cleaning tanks and equipment—requires vast amounts of water. The wastewater discharged from these activities is rich in fats, proteins, lactose, cleaning chemicals, and organic loads that can severely damage drainage systems, rivers, and groundwater if not treated properly.

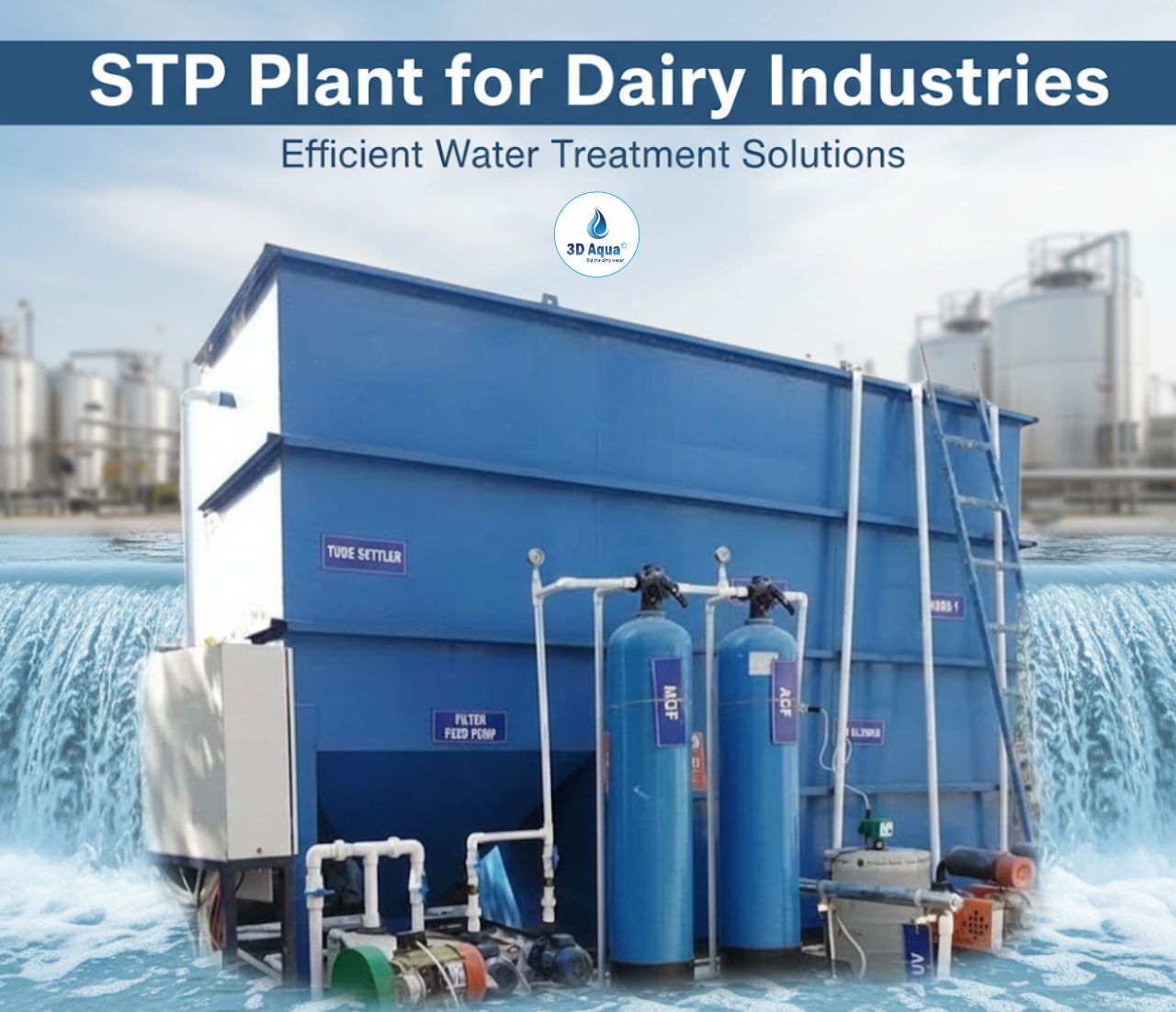

This is where a Sewage Treatment Plant (STP) for dairy industries plays a vital role. By implementing a well-planned STP system, dairy plants can control pollution, meet legal compliance, cut down water consumption, and lower operational costs. Beyond regulatory obligations, wastewater treatment in dairy facilities ensures community health and environmental protection, while allowing treated water to be reused for secondary purposes like cleaning, cooling, and gardening.

In this article, we will explore the challenges of dairy wastewater, the importance of STPs, the core treatment processes, system design considerations, and operation and maintenance strategies that make dairy wastewater treatment efficient and sustainable.

Why Dairy Wastewater is Challenging

Unlike domestic sewage, dairy effluent contains a unique mixture of organic and inorganic pollutants. Some of the key challenges include:

- High Organic Load (BOD & COD): Dairy wastewater has high biochemical oxygen demand (BOD) and chemical oxygen demand (COD) due to milk solids, fats, and sugars. If released untreated, it depletes oxygen in water bodies and harms aquatic life.

- Fats, Oils & Grease (FOG): Fatty matter in wastewater can clog pipelines, create floating layers in treatment tanks, and reduce microbial efficiency.

- Suspended Solids: Residual curd, whey, and other solids settle in drains and increase sludge production.

- Cleaning Chemicals: Detergents, sanitizers, and caustic soda used for CIP (Cleaning-in-Place) processes alter pH and disturb biological treatment processes.

- Seasonal Variation: Wastewater quality and volume fluctuate depending on production cycles and peak seasons.

To handle these challenges, STPs for dairy industries require a combination of physical, chemical, and biological treatment methods designed for robustness and flexibility.

Importance of STP Plants in Dairy Industries

1. Protecting the Environment & Public Health

A well-functioning STP ensures the removal of solids, oils, and harmful organic matter before wastewater leaves the plant premises. This prevents foul odor, water contamination, and damage to rivers and soil. Clean discharge keeps the local community safe and helps the company maintain a positive image.

2. Meeting Legal Compliance

Dairy plants are bound by pollution control board norms that set strict discharge limits. Non-compliance can lead to heavy fines, plant shutdowns, and legal liabilities. An efficient STP helps the industry maintain compliance through continuous monitoring and accurate reporting.

3. Saving Water & Reducing Costs

Water is a critical resource for dairy industries. With STP systems, treated wastewater can be recycled for cleaning, cooling towers, and non-potable uses, reducing dependence on fresh water. This not only cuts costs but also ensures a reliable supply during water-scarce periods.

4. Supporting Sustainability Goals

Modern consumers and governments expect industries to adopt eco-friendly practices. By treating and reusing wastewater, dairy companies demonstrate their commitment to sustainability, making their operations more socially responsible and future-ready.

Core Components of STP for Dairy Industries

1. Preliminary Treatment & Oil Removal

- Screens, grit chambers, and oil skimmers remove large solids, sand, and floating fat.

- Prevents downstream clogging and protects pumps, membranes, and aerators.

2. Primary Treatment

- Equalization tanks balance the flow and pollutant load.

- Dissolved Air Flotation (DAF) systems are often used to separate fats, oils, and suspended solids.

3. Biological Treatment & Aeration

- Microorganisms break down proteins, sugars, and organic matter.

- Aeration tanks provide oxygen, ensuring efficient microbial activity.

- Technologies used: Activated Sludge Process (ASP), Sequencing Batch Reactor (SBR), Moving Bed Biofilm Reactor (MBBR), or Membrane Bioreactor (MBR) depending on plant size and goals.

4. Clarification & Polishing

- Secondary clarifiers settle biomass and suspended solids.

- Tertiary treatment options include sand filters, activated carbon filters, ultrafiltration (UF), or reverse osmosis (RO) for high-quality discharge.

5. Sludge Management

- Sludge thickening, digestion, and dewatering minimize waste volume.

- Treated sludge can be composted or used as manure in agriculture.

Designing STPs for Dairy Industries

The success of a dairy STP depends largely on customized design tailored to the plant’s operations. Key considerations include:

1. Flow & Load Study

Accurate measurement of daily flow, peak loads, and pollutant levels is crucial for sizing tanks and selecting equipment. Under-designed plants fail to meet standards, while over-designed systems increase costs.

2. Modular & Flexible Layouts

Modular systems allow capacity expansion without disrupting operations. This is especially useful for dairies with seasonal demand or expansion plans.

3. Automation & Controls

- Sensors monitor pH, oxygen levels, turbidity, and sludge age.

- SCADA systems and IoT-based controls reduce manual intervention and ensure consistent performance.

4. Energy & Cost Efficiency

Aeration is the most energy-intensive process. Using fine bubble diffusers, energy-efficient blowers, and VFDs (Variable Frequency Drives) helps reduce electricity consumption.

Operation, Maintenance & Compliance

1. Daily Operator Checks

- Monitoring pumps, aerators, valves, and sensors.

- Logging chemical dosages and plant performance parameters.

- Quick troubleshooting ensures uninterrupted treatment.

2. Preventive Maintenance

- Regular servicing of blowers, pumps, and membranes avoids costly breakdowns.

- Maintaining a stock of essential spare parts ensures continuity during emergencies.

3. Monitoring, Reporting & Audits

- Continuous monitoring provides data for pollution control audits.

- Accurate reporting builds trust with regulators and demonstrates commitment to compliance.

4. Training & Safety

- Skilled operators are essential for effective wastewater treatment.

- Regular training ensures operators can handle biological fluctuations, chemical dosing, and system alarms efficiently.

Best Practices & Innovative Approaches

- Anaerobic Digesters: Generate biogas from high-strength dairy sludge, reducing energy costs.

- Zero Liquid Discharge (ZLD): Advanced systems eliminate liquid waste by recovering maximum water and crystallizing salts.

- Water Reuse Applications: Treated water can be reused for boiler feed, cooling towers, irrigation, and cleaning processes.

- Real-Time Monitoring: Smart sensors and cloud-based dashboards ensure early detection of performance deviations.

Conclusion

The dairy industry’s growth is directly tied to its ability to manage water responsibly. STP plants for dairy industries are not just about meeting regulatory compliance—they are about protecting the environment, lowering operational costs, and ensuring business continuity.

By combining preliminary treatment, biological processes, polishing steps, and robust sludge management, dairies can significantly reduce their ecological footprint. When designed and operated correctly, STPs enable water recycling, energy savings, and long-term sustainability.

If you are a dairy plant operator or business owner looking to upgrade or install a new wastewater treatment system, 3D Aqua provides customized solutions tailored to your flow, load, and budget requirements.

📞 Contact 3D AQUA

- Phone: +91-6262629090

- Email: info@3daqua.in