When it comes to wastewater treatment, selecting the right Sewage Treatment Plant (STP) is crucial for maintaining environmental standards, meeting regulatory compliance, and ensuring long-term sustainability. In India, the Pollution Control Board (PCB) has set clear guidelines for water treatment practices, prompting industries and municipalities to adopt efficient technologies. Among the various options, Membrane Bioreactors (MBR) and Moving Bed Biofilm Reactors (MBBR) stand out as two leading solutions for wastewater treatment. Both offer distinct benefits and are suitable for different applications. In this article, we’ll compare MBR and MBBR systems to help you decide which one best fits your needs.

What is an MBR (Membrane Bioreactor)?

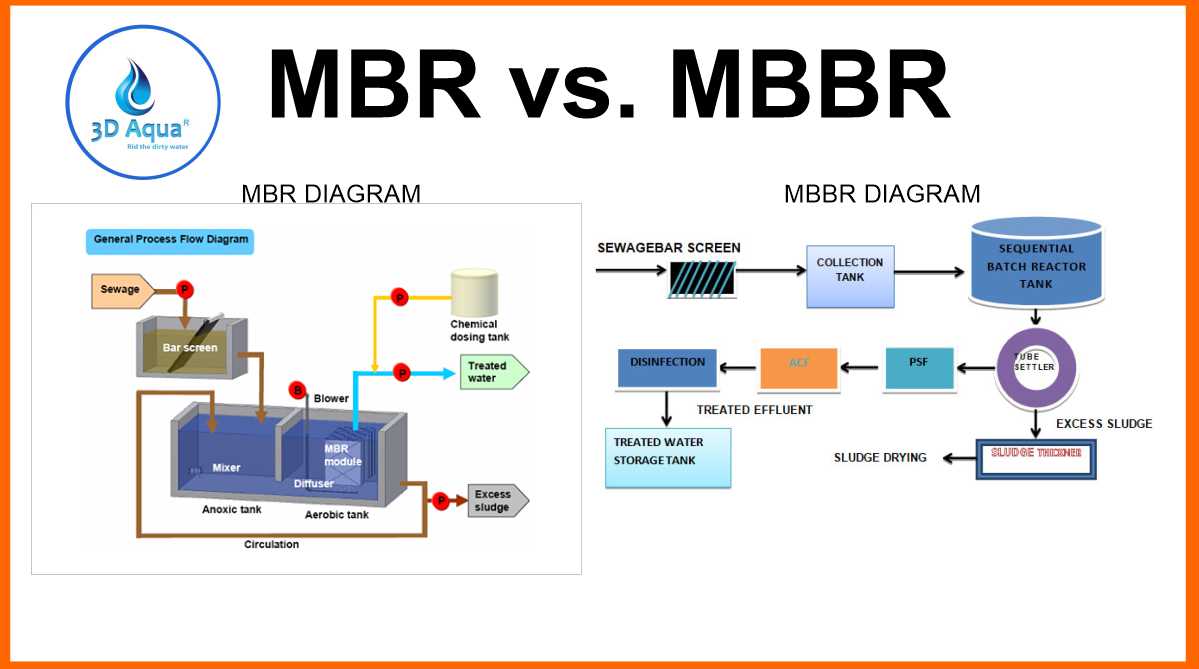

A Membrane Bioreactor (MBR) combines biological treatment with membrane filtration technology, offering a highly efficient method for treating wastewater. MBR systems are widely recognized for producing high-quality effluent that meets strict discharge standards, making them ideal for areas with stringent environmental regulations.

Key Features of MBR Systems:

- High-Quality Effluent: The MBR system incorporates a biological treatment process followed by membrane filtration. This ensures that the treated water is free of suspended solids, pathogens, and other contaminants. As a result, MBR systems produce effluent of superior quality, making it suitable for reuse in agricultural irrigation, industrial processes, and even potable applications, depending on the treatment level.

- Space-Efficient: MBR systems are compact, making them ideal for locations with limited space. The high biomass concentration within the bioreactor reduces the need for large tanks, allowing these systems to fit into smaller footprints.

- Stringent Discharge Standards: For projects that require compliance with stringent regulatory discharge limits, MBR is the ideal choice. The quality of effluent generated by MBR systems meets the most demanding water quality requirements.

- High Initial Costs: The advanced technology behind MBR systems comes with higher upfront capital costs. Additionally, regular maintenance of the membranes is necessary, adding to operational expenses. However, the quality of effluent produced justifies the investment for many industries and municipalities. Read more here about MBR Technology

What is an MBBR (Moving Bed Biofilm Reactor)?

The Moving Bed Biofilm Reactor (MBBR) operates on a different principle. MBBR uses freely moving plastic carriers to support biofilms that break down organic contaminants in wastewater. The biofilms are cultivated on these carriers, which move with the flow of wastewater, allowing bacteria to treat the wastewater by converting organic materials into simpler, inorganic substances.

Key Features of MBBR Systems:

- Robustness and Flexibility: MBBR systems are designed to handle fluctuating loads, making them ideal for municipal and industrial applications where wastewater flows may vary. These systems can accommodate shock loads and organic loading variations, offering a flexible solution to unpredictable wastewater inflow.

- Simple Operation and Maintenance: Compared to MBR systems, MBBR plants are easier to operate and maintain. They do not require regular membrane cleaning or replacement, which makes them less labor-intensive and more straightforward for operators to manage.

- Cost-Effectiveness: MBBR systems are generally more affordable in terms of initial installation and ongoing operational costs. This makes MBBR an attractive option for projects with budget constraints, as they deliver reliable performance without the high price tag associated with MBR systems.

- Moderate Effluent Quality: Although MBBR produces treated water of acceptable quality, it may not meet the stringent reuse criteria without additional post-treatment. While it is effective for many applications, MBBR effluent may require further polishing steps if higher-quality water is needed. Read more here about MBR Technology

Key Differences Between MBR and MBBR:

Understanding the differences between MBR and MBBR can help you make a more informed decision based on your specific needs. Below is a comparison of the two systems based on key criteria:

1. Effluent Quality:

- MBR: Known for producing high-quality effluent with minimal suspended solids and pathogens. It is suitable for situations with stringent water quality standards.

- MBBR: While effective, the effluent quality is generally lower than that of MBR. MBBR may need additional treatment processes to meet high-quality standards for water reuse.

2. Space Efficiency:

- MBR: MBR systems are compact and space-efficient due to the high concentration of biomass within the bioreactor.

- MBBR: MBBR systems require more space than MBR due to the need for larger tanks to accommodate the moving biofilm carriers.

3. Cost:

- MBR: Typically involves higher capital and operational costs due to advanced technology and membrane maintenance requirements.

- MBBR: Generally more cost-effective, both in terms of initial investment and ongoing operational expenses.

4. Operational Complexity:

- MBR: Requires more sophisticated operation, including the maintenance and cleaning of membranes. It also requires trained personnel to manage the system.

- MBBR: Easier to operate and maintain, with less frequent need for maintenance. This makes it suitable for smaller operations or less complex wastewater treatment needs.

How to Choose the Right STP for Your Needs?

Choosing between MBR and MBBR depends on several factors, including space availability, budget, wastewater characteristics, and regulatory requirements. Below are some guidelines to help you make the right choice:

1. Space Constraints:

If you are working with limited space, MBR is likely the better option. Its compact design allows it to fit in smaller spaces, making it ideal for urban areas or locations with land limitations.

2. Budget Considerations:

MBBR is the more cost-effective option for those working within a tight budget. With lower initial investment and reduced operational costs, MBBR systems are a popular choice for cost-conscious projects.

3. Water Quality Requirements:

If your project requires high-quality effluent that meets strict discharge standards or is intended for reuse in sensitive applications, MBR is the ideal choice. On the other hand, MBBR may be sufficient for less stringent requirements or where additional treatment steps can be implemented later.

4. Ease of Operation:

If simplicity and ease of operation are important factors, MBBR will likely be a better fit. Its straightforward operation and lower maintenance needs make it a suitable option for facilities with less experienced staff or smaller-scale operations.

5. Industrial or Municipal Application:

For large-scale municipal or industrial applications with fluctuating wastewater loads, MBBR’s ability to handle varying wastewater characteristics makes it a robust solution. MBR, though excellent in quality, is often best suited for smaller, more controlled systems where space and discharge standards are crucial.

3D Aqua: Expert in MBR & MBBR STP Plants Designing, Installation & AMC (1KLD to 2MLD)

Conclusion: Which STP System Should You Choose?

Both Membrane Bioreactors (MBR) and Moving Bed Biofilm Reactors (MBBR) offer distinct advantages depending on your specific needs and circumstances. MBR systems are ideal for high-efficiency, high-quality effluent applications, particularly in locations with space limitations and strict discharge requirements. On the other hand, MBBR systems are cost-effective, flexible, and robust, making them a suitable choice for less stringent quality requirements, larger flow variations, and more straightforward operational needs.

Ultimately, your decision should be based on factors such as available space, budget, effluent quality requirements, and operational complexity. If you’re unsure about which system best suits your needs, consulting with experts in wastewater treatment technology can help ensure you make the most informed decision for your project.

Need Help Deciding?

If you’re still unsure about whether MBR or MBBR is the right choice for your STP, don’t hesitate to reach out to experts who specialize in wastewater management. At 3D Aqua Water Treatment Company, we provide tailored advice and solutions to simplify your decision-making process. Our experienced team is here to guide you through the selection, installation, and operation of your STP, ensuring you meet your goals while adhering to environmental regulations.

Contact us today at 6262629090 or visit our website at 3daqua.in for more information and personalized consultation. Together, we can work toward achieving efficient, economical, and sustainable wastewater treatment systems that benefit both your business and the environment.