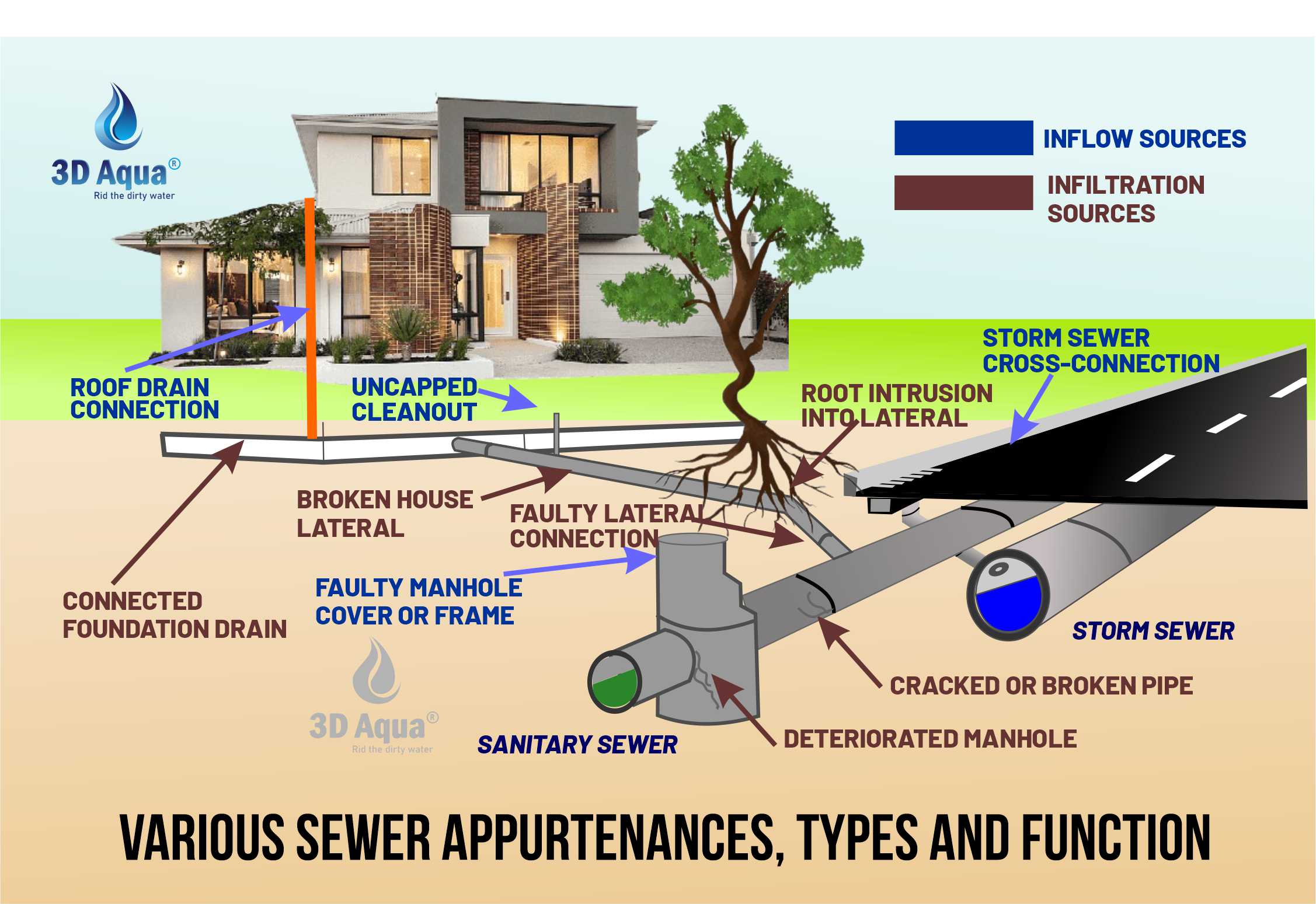

Sewer appurtenances play a crucial role in maintaining the efficiency and functionality of sewerage systems. These essential components are strategically placed along sewer lines to ensure smooth operation, easy maintenance, and effective management of wastewater.

Essential Sewer Appurtenances: Key Components for Efficient Drainage Systems

Here’s a comprehensive guide to the various types of sewer appurtenances and their functions:

- Manholes: Manholes are access points to sewer systems, constructed from reinforced concrete or masonry. These openings, typically circular or rectangular, allow personnel to enter sewers for inspection, cleaning, and maintenance. Manholes also act as ventilation points for sewers and facilitate the installation of sewer lines in manageable lengths. They are strategically placed at bends, junctions, changes in sewer diameter, or alterations in direction or gradient.

- Drop Manholes: Drop manholes are specialized manholes designed for areas where there is a significant elevation difference between a branch sewer and the main sewer. They manage the vertical drop of sewage, ensuring smooth flow and reducing the risk of blockages.

- Lamp-holes: Positioned between manholes on long, straight sewer lines, lamp-holes provide a means to lower a lamp or other inspection devices into the sewer to identify obstructions. They also facilitate sewer flushing and maintenance activities.

- Street Inlets: Street inlets are openings located on the edges of road pavements, designed to capture stormwater and direct it into storm sewers or combined sewers. These inlets are spaced at intervals of up to 30 meters to efficiently manage surface runoff.

- Catch Basins: Catch basins are small settling chambers installed below street inlets. They trap heavy debris, grit, and sand, preventing these materials from entering the sewer system. By reducing the velocity of stormwater entering the sewer, catch basins help in maintaining the sewer’s operational efficiency.

- Inverted Siphons: Also known as depressed sewers, inverted siphons are sections of sewer lines that flow full under pressure greater than atmospheric pressure. They are used where sewers cross streams, deep cuts, or roadways. Inverted siphons are equipped with sluice valves for cleaning and maintenance by adjusting the flow head.

- Clean-Outs: Clean-outs are access points for sewer cleaning and maintenance, typically installed at the upper ends of lateral sewers. They consist of a capped, inclined pipe that connects to the sewer line underground, with the top end accessible at ground level for easy maintenance.

- Flushing Devices: Flushing devices help prevent sewer blockages by introducing water into the sewer system to maintain self-cleansing velocity. They are particularly useful in maintaining flatter sewer gradients that might otherwise be prone to clogging.

- Grease and Oil Traps: Grease and oil traps are specialized devices installed to intercept grease and oil before they enter the sewer system. These traps are commonly placed near sources of grease and oil, such as automotive repair shops, kitchens in hotels, and industrial facilities, to prevent sewer clogs and maintain system efficiency.

- Storm Water Regulators: Storm water regulators, or overflow devices, are essential for managing excess sewage in combined sewer systems. They divert overflow through relief sewers to watercourses, preventing overloading of sewers, pumping stations, and treatment plants.

Conclusion

Sewer appurtenances are vital for the proper functioning and maintenance of any drainage system. From manholes and drop manholes to grease traps and storm water regulators, each component plays a specific role in ensuring efficient wastewater management. For more information on selecting the right wastewater treatment solutions, consider reaching out to experts in the field. Company like 3D Aqua specialize in manufacturing and maintaining advanced water and wastewater treatment plants, offering comprehensive support and solutions tailored to your needs.

For further assistance or inquiries, contact 3D Aqua, a leading manufacturer of water and wastewater treatment plants in India. Call +91-8963089630 or email info@3daqua.in for expert advice and support.