DM Water Treatment Plant

Original price was: ₹39,000.00.₹35,000.00Current price is: ₹35,000.00.

Get high-purity water with 3D Aqua DM Water Treatment Plants. Ideal for pharma, labs & industry. Call 6262629090 for custom quote & installation.

Description

DM Water Treatment Plant – Complete Solution for Pure De-Mineralized Water

In today’s industries, the need for ultra-pure water is essential across various processes. Whether it’s boiler feed water, pharmaceutical manufacturing, food processing, or laboratory usage, De-Mineralized (DM) Water plays a crucial role in maintaining product quality, system longevity, and process efficiency. To produce this high-purity water, industries rely on the DM Water Treatment Plant, a proven system that removes dissolved salts and ions through ion exchange technology.

3D Aqua Water Treatment Company is one of India’s leading manufacturers and suppliers of DM Water Plants, offering state-of-the-art, custom-designed solutions tailored to specific industry needs. Our systems ensure consistent water quality, reduce scaling, and optimize your operational performance.

📞 Call Now for Quotation – 6262629090

📧 Email – info@3daqua.in

🌐 Website – www.3daqua.in

🔷 What Is a DM Water Plant?

A DM (De-Mineralized) Water Plant is a specialized water purification system that removes dissolved mineral salts (both cations and anions) from raw water using ion exchange resins. The result is water with extremely low conductivity, free from mineral ions such as calcium, magnesium, sodium, chloride, sulfate, nitrate, etc.

This pure water is required in critical applications where the presence of any ionic contamination can disrupt chemical processes, corrode equipment, or compromise product standards.

🔷 How DM Water Plant Works – Ion Exchange Process

DM water treatment works on the ion exchange principle, where positively and negatively charged resins replace unwanted ions in the water with hydrogen (H⁺) and hydroxyl (OH⁻) ions. These combine to form pure water (H₂O), free from dissolved salts.

✔️ Cation Exchange

Removes positively charged ions like Calcium (Ca²⁺), Magnesium (Mg²⁺), Sodium (Na⁺), and Iron (Fe²⁺) and replaces them with H⁺ ions.

✔️ Anion Exchange

Removes negatively charged ions like Chloride (Cl⁻), Sulfate (SO₄²⁻), Nitrate (NO₃⁻), and Bicarbonate (HCO₃⁻), replacing them with OH⁻ ions.

✔️ Final Output

The H⁺ and OH⁻ ions from both exchanges combine to produce H₂O – pure, demineralized water.

Some advanced systems include a Mixed Bed Polisher for ultra-pure water, polishing the last trace of ions after cation/anion exchange.

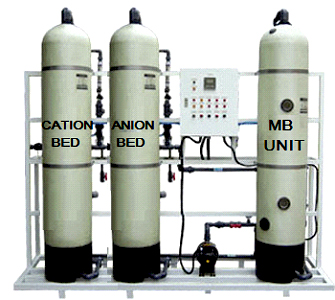

🔷 Key Components of a DM Plant

A standard DM Water Plant includes the following components:

| Component | Function |

|---|---|

| Cation Exchange Unit | Removes all positively charged ions. |

| Anion Exchange Unit | Removes all negatively charged ions. |

| Degasifier Tower (optional) | Removes CO₂ gas formed from bicarbonates after cation unit. |

| Mixed Bed Unit (optional) | Final polishing for ultra-pure water. |

| FRP/MS Vessel | Durable structure for housing the resin media. |

| Multiport Valves | For efficient switching between service, backwash, and regeneration. |

| Regeneration System | Acid and alkali dosing for resin recharge. |

| Conductivity Meter | Measures water purity in µS/cm. |

🔷 Types of DM Water Plants Offered by 3D Aqua

We manufacture DM Plants in a variety of designs and capacities depending on your flow rate, purity requirements, and usage environment.

✅ Manual DM Plant

Low-cost, easy-to-operate unit using manual valves for switching cycles. Best for labs, schools, and light industrial use.

✅ Semi-Automatic DM Plant

Some automation in backwash and regeneration cycles. Ideal for moderate use.

✅ Fully Automatic DM Plant

PLC-based or timer-controlled units with full automation for large-scale, uninterrupted industrial usage.

✅ Two-Bed DM Plant

Consists of one cation and one anion unit. Removes 90–95% of dissolved solids.

✅ Mixed Bed DM Plant

Used as a polishing unit after the two-bed plant for high-purity applications (conductivity <1 µS/cm).

🔷 DM Water Plant Applications

DM Plants are essential in industries and processes that require high-purity water. Here’s where they are commonly used:

🏭 Industrial Applications:

- Boiler Feed Water – Prevent scaling and corrosion in high-pressure boilers.

- Cooling Towers – Avoid salt deposition and enhance system life.

- Textile & Dyeing – Prevent color variation due to mineral presence.

- Chemical Manufacturing – For reactions requiring controlled environments.

- Electronics & PCB Industry – Rinse and process circuits in mineral-free water.

💊 Pharmaceutical & Medical:

- Formulation of drugs

- Sterilization of equipment

- Cleanroom humidifiers

- Dialysis Units

🔬 Laboratories & Research:

- Sample testing

- Chemical mixing

- Glassware rinsing

🥫 Food & Beverage:

- Ingredient water for beverages

- Bottling plants

- CIP (Clean-in-Place) operations

🔷 Benefits of Using DM Water

- ✅ Ultra-Pure Water – Achieves conductivity < 1 µS/cm for critical uses.

- ✅ Scale Prevention – Eliminates risk of scaling in boilers and equipment.

- ✅ Improved Product Quality – No contamination from salts or minerals.

- ✅ Increased Equipment Life – Corrosion-free operations.

- ✅ Cost Savings – Reduces maintenance, downtime, and chemical use.

- ✅ Eco-Friendly – No chlorine or harmful chemical discharge during use.

🔷 DM Water Plant Capacity Range

We manufacture DM Plants from 50 LPH to 100,000 LPH:

| Plant Capacity (LPH) | Ideal For |

|---|---|

| 100–250 LPH | Labs, Schools, Small Clinics |

| 500–1000 LPH | Clinics, Light Industry |

| 2000–5000 LPH | Pharmaceuticals, Boiler Feed |

| 10,000–50,000 LPH | Heavy Industry, Chemical Plants |

| 100,000 LPH and above | Power Plants, Refineries, OEM Use |

Custom capacities and modular designs are available upon request.

🔷 Maintenance and Regeneration of DM Plants

Ion exchange resins become saturated after treating a specific volume of water and need to be regenerated.

🛠 Regeneration Process:

- Cation Resin: Regenerated with Hydrochloric Acid (HCl)

- Anion Resin: Regenerated with Sodium Hydroxide (NaOH)

Regular regeneration ensures consistent water quality. Regeneration frequency depends on water hardness, TDS level, and plant usage.

🧪 Testing & Monitoring:

-

Use conductivity meters to track water purity.

-

Regenerate when conductivity exceeds 10–20 µS/cm or per scheduled cycle.

🔷 Why Choose 3D Aqua for DM Plants?

- 🏆 Industry Leader with 10+ years in water treatment

- ⚙️ Custom Design as per specific water chemistry

- 🧰 Robust Materials – FRP, MSRL, SS as required

- 💼 Installation & Commissioning support across India

- 🧪 Free Water Testing & Plant Design Consultation

- 🔄 Annual Maintenance Contracts (AMC)

- 📦 Prompt Delivery & After-Sales Service

🔷 Technical Specifications Snapshot

| Parameter | Typical Range |

|---|---|

| Raw Water TDS | < 500 ppm (recommended) |

| Output Water Conductivity | < 1 µS/cm (with mixed bed) |

| Operating Pressure | 2–3.5 kg/cm² |

| pH Range for Operation | 6.5 – 7.5 |

| Regeneration Frequency | After every 5–10 m³ (varies) |

| Vessel Material | FRP / Mild Steel / Stainless Steel |

| Valve Type | Manual / Automatic / Pneumatic |

🔷 DM Water vs RO Water – What’s the Difference?

| Criteria | DM Water | RO Water |

|---|---|---|

| Purification Method | Ion Exchange | Membrane Filtration |

| Removes Dissolved Salts | ✅ Yes | ✅ Yes |

| Removes Microbes | ❌ No | ✅ Yes (partially) |

| Output Conductivity | < 1 µS/cm (with mixed bed) | ~5–30 µS/cm |

| Chemical Requirement | Acid & Caustic for regeneration | No chemicals |

| Cost | Lower initial, higher OPEX | Higher initial, low OPEX |

For ultra-pure water, DM Plants are still unmatched in conductivity, but RO systems are better for microbial safety.

🔷 Safety Tips During Operation

- Always use PPE (gloves, goggles) when handling acid/alkali.

- Regeneration should be performed in well-ventilated areas.

- Train staff in proper valve operations and chemical handling.

- Dispose of regenerant chemicals as per local environmental norms.

🔷 Customer Testimonials

“We’ve been using a 3000 LPH DM Plant from 3D Aqua in our pharma unit. Excellent build quality and after-sales support!”

– Dr. Raghav, Pharmacist, Baddi

“Their team customized our 10K LPH DM Plant for textile processing. Very happy with the performance and water quality.”

– Prakash Kumar, Plant Manager, Surat

🔷 Order Your DM Plant from 3D Aqua Today

Whether you’re a small lab or a large industrial facility, we have the right DM Water Plant solution for you. With precision engineering, responsive service, and certified quality, 3D Aqua is your trusted partner in water treatment.

📞 Call Now – 6262629090

📧 Email – info@3daqua.in

🌐 Website – www.3daqua.in

Let’s work together to bring ultra-pure water to your process.

Reviews

There are no reviews yet.