The baffling factor plays a pivotal role in the design and operation of water treatment systems. Whether you’re dealing with a drinking water treatment plant, a wastewater facility, or any industrial system that requires effective water treatment, understanding and calculating the baffling factor is essential. The baffling factor measures the efficiency of water flow and helps engineers optimize tank design for better mixing and sufficient contact time for disinfection.

In this article, we’ll walk through the fundamental concepts, methods of calculation, and practical applications of the baffling factor. We’ll also explore how this calculation can be used to improve the performance of water treatment systems, ensuring safe and efficient water processing.

What is the Baffling Factor?

The baffling factor is a key parameter used to assess the flow characteristics of water through treatment tanks. It essentially measures the degree to which water is mixed within a tank and how effectively the water and disinfectants come into contact during the treatment process. The term “baffling” refers to the physical barriers (called baffles) inside the tank that are designed to control the flow of water and reduce short-circuiting.

A baffling factor closer to 1.0 indicates that the flow through the tank is well-distributed, and the tank design facilitates effective contact between water and chemicals such as disinfectants. In contrast, a lower baffling factor (closer to 0.1) suggests poor mixing and inefficient contact time, which could compromise the disinfection process.

Why is the Baffling Factor Important?

The primary reason for calculating the baffling factor is to ensure that the water treatment process, especially disinfection, is as efficient as possible. Several factors rely on this calculation:

- Contact Time: Disinfection processes such as chlorination or ozonation rely on water having enough time in contact with disinfectants. A proper baffling factor ensures that the required contact time is achieved.

- Flow Patterns and Mixing Efficiency: The baffling factor directly affects flow patterns within a tank. Poor baffling can lead to stagnant areas or short-circuiting, reducing the effectiveness of the treatment.

- Regulatory Compliance: Water treatment plants must meet certain standards for water quality. Accurate baffling factor calculations help ensure that the plant complies with these regulations.

- Operational Efficiency: Effective baffling leads to optimized chemical dosing and efficient water flow, which improves plant performance and reduces operational costs.

Basic Concepts Behind the Baffling Factor Calculation

1. Flow Patterns

Water flow in a treatment tank can be complex. A well-designed tank should ensure that the water flows uniformly through the entire volume, allowing it to interact properly with any added chemicals. Short-circuiting (when water bypasses the treatment process and does not spend enough time in the tank) is a common issue that reduces the tank’s efficiency. The baffling system inside the tank helps prevent such short-circuiting and ensures that water moves through the tank in a more controlled manner, allowing proper mixing and effective disinfection.

2. Retention Time

Retention time refers to the amount of time the water stays in the treatment tank. Theoretical retention time is the time calculated based on the volume of the tank and the flow rate of the incoming water. However, the actual retention time may differ due to inefficiencies in the tank design (like short-circuiting or poor mixing). The baffling factor helps engineers calculate the actual retention time by accounting for these variations.

3. Tracer Studies

Tracer studies involve introducing a non-toxic dye or tracer into the treatment tank to visualize how water moves through the tank. The tracer allows engineers to observe flow patterns, detect dead zones, and determine the actual contact time. These studies are crucial for accurately calculating the baffling factor because they provide real-world data on how water behaves within the tank, rather than relying solely on theoretical calculations.

How to Calculate the Baffling Factor

The calculation of the baffling factor requires both theoretical and actual measurements, including tracer study data. Let’s break down the basic steps involved:

Basic Formula for Baffling Factor Calculation

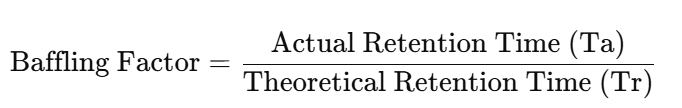

The simplest method for calculating the baffling factor involves comparing the theoretical retention time (Tr) to the actual retention time (Ta). The formula is as follows:

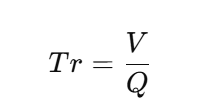

- Theoretical Retention Time (Tr): This is calculated by dividing the volume of the tank (V) by the flow rate (Q) of incoming water:

- Actual Retention Time (Ta): This is determined through tracer studies, where the time it takes for the tracer to move through the tank is measured. The actual retention time is typically longer than the theoretical time due to inefficiencies in the tank design.

The baffling factor will typically range from 0.1 (poor baffling) to 1.0 (optimal baffling). A factor closer to 1.0 indicates efficient mixing and adequate contact time for disinfection, while a factor below 0.5 often signals that there are design issues with the tank.

Tracer Study Method

Tracer studies are essential for obtaining the actual retention time. Here’s how you can conduct a tracer study:

- Introduce a Tracer: A non-toxic tracer (such as a dye or salt) is introduced into the inflow of the tank.

- Track the Movement: As the water flows through the tank, sensors or sampling points measure the tracer’s concentration at various locations in the outflow.

- Analyze the Data: The time it takes for the tracer to travel through the tank, along with the concentration profile, helps determine the actual retention time.

- Calculate the Baffling Factor: Once you have the actual retention time from the tracer study, you can use the formula above to calculate the baffling factor.

Advanced Calculations for Complex Systems

For more complex systems, such as those with multiple flow paths or irregular tank shapes, additional computational tools and advanced calculations are often necessary. Engineers may use computational fluid dynamics (CFD) simulations or other modeling software to simulate water flow in the tank and refine the baffling factor calculation.

These advanced methods allow for detailed analysis of the system’s flow patterns, enabling engineers to optimize tank design and make adjustments that can improve baffling efficiency.

Adjusting for Tank Modifications

Sometimes, tank modifications (e.g., adding more baffles, adjusting the flow rate) are required to optimize baffling. If the design is changed, it’s important to recalculate the baffling factor to assess the impact of these adjustments on the tank’s efficiency.

Practical Applications of Baffling Factor in Water Treatment

1. Disinfection Systems

The baffling factor directly impacts the disinfection process in water treatment plants. For example, in chlorine contact tanks, the contact time between the water and chlorine is critical for ensuring effective disinfection. By accurately calculating the baffling factor, engineers can ensure that the chlorine remains in contact with the water long enough to kill harmful pathogens. Insufficient contact time may lead to ineffective disinfection, while excessive contact time can result in chlorine overdosing, which affects water taste and may have health implications.

2. System Design and Optimization

Baffling factor calculations are used to design more efficient treatment tanks. For example, by improving the baffling in a tank, engineers can reduce dead zones and improve flow distribution, leading to more effective treatment processes. This can also reduce the need for additional chemical dosing, thus optimizing the operational costs of the plant.

3. Performance Monitoring and Troubleshooting

After a treatment system is up and running, ongoing monitoring of the baffling factor can help assess system performance. If the baffling factor is lower than expected, it might indicate that the tank design needs modifications or that operational conditions have changed (such as a shift in water flow rate). Regularly testing the baffling factor allows operators to spot potential issues early, improving overall system reliability.

Conclusion: The Importance of Accurate Baffling Factor Calculations

Calculating the baffling factor is essential for the efficient design, operation, and maintenance of water treatment systems. By accurately determining this factor, engineers can optimize tank performance, ensure adequate contact time for disinfection, and prevent issues such as short-circuiting and inadequate mixing.

From disinfection processes to performance monitoring, understanding the baffling factor provides water treatment plants with the tools they need to meet regulatory standards and ensure the delivery of safe, clean water to communities.

If you need help calculating the baffling factor for your water treatment system, or if you’re looking for expert assistance with tracer studies and system analysis, contact our team at 3D Aqua Water Treatment Company. We offer comprehensive solutions to optimize your treatment system’s performance.

Contact 3D Aqua Water Treatment Company

For tailored wastewater treatment solutions, including STP, ETP, Ultrafiltration and RO systems, reach out to us at:

- Phone: +91-89630-89630

- Email: info@3daqua.in