The electronics industry is one of the most demanding sectors in the world. Whether it is semiconductors, microchips, circuit boards, or flat-panel displays, the quality of electronic products depends on precision and absolute cleanliness. Even the smallest impurity can cause catastrophic failure in delicate electronic components.

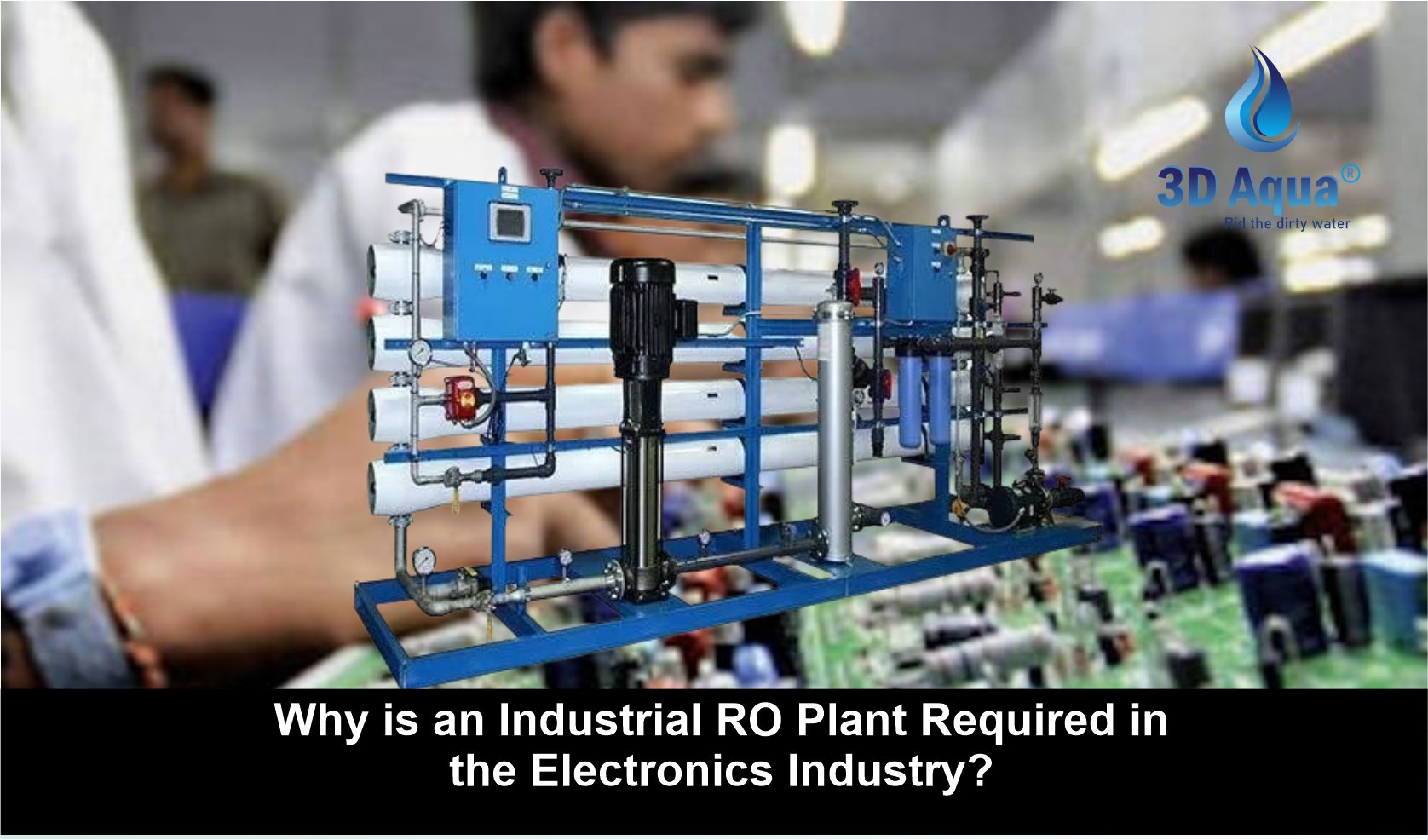

To overcome this challenge, industries rely on Industrial Reverse Osmosis (RO) Plants. These advanced water purification systems produce ultra-pure water (UPW) that is free from dissolved solids, organic matter, gases, bacteria, and ions. From wafer fabrication to semiconductor cleaning, RO technology plays a critical role in ensuring flawless production.

But why is an Industrial RO Plant so essential in electronics manufacturing? How does it work, and what makes it different from other purification technologies? This detailed guide answers those questions while highlighting its applications, advantages, and future relevance.

Understanding Reverse Osmosis in Simple Terms

At its core, Reverse Osmosis is like a super-fine filter that only allows water molecules to pass through while blocking everything else.

Here’s how it works:

- Water is pushed across a semi-permeable membrane using high pressure.

- The membrane allows only pure water molecules to pass.

- Impurities such as ions, salts, bacteria, and organic matter are left behind.

- The result is ultra-pure water on one side and concentrated waste (brine) on the other.

This principle makes RO one of the most effective methods of producing highly purified water suitable for sensitive industrial processes.

Why Electronics Manufacturing Needs Ultra-Pure Water

The electronics industry is different from most others because the tiniest contaminant can ruin a batch of products worth millions of dollars. Ordinary filtered water or softened water simply isn’t enough. The industry requires Ultra-Pure Water (UPW) with a purity level close to theoretical perfection.

RO plants make this possible by eliminating:

- Dissolved salts and minerals (that can cause deposits on circuits)

- Organic compounds (that interfere with chemical processes)

- Bacteria and microorganisms (that degrade sensitive materials)

- Suspended particles (that scratch or corrode surfaces)

- Dissolved gases like carbon dioxide and oxygen (that alter conductivity)

Issues Caused by Impure Water in Electronics Production

- Corrosion of metal parts – Even trace minerals or salts can corrode copper tracks or metal contacts.

- Reduced electrical conductivity – Impurities create inconsistencies in electronic signals.

- Defects in semiconductor wafers – Dust, salts, or organics on wafers can block etching and layering.

- Shorter product lifespan – Impurities accelerate degradation in finished devices.

This is why RO plants are not just useful but absolutely necessary for electronics manufacturing.

Key Applications of Industrial RO Plants in the Electronics Industry

Let’s break down how and where RO-purified water is used in electronics production:

1. Semiconductor Manufacturing

Semiconductors are the backbone of modern electronics. Each wafer requires multiple chemical baths and rinses during fabrication. RO plants ensure these baths contain only ultra-pure water, preventing contamination.

- Ensures flawless etching and layering on wafers.

- Reduces ionic contamination that affects chip performance.

- Increases yield by lowering rejection rates.

2. Printed Circuit Board (PCB) Fabrication

PCBs are essential in everything from smartphones to automobiles. During plating, cleaning, and etching, impurities can lead to poor adhesion or short circuits.

- RO water provides clean rinsing for PCBs.

- Prevents stains, scaling, and spotting.

- Enhances the conductivity and reliability of the finished product.

3. Flat Panel and LCD Manufacturing

Large amounts of pure water are required to clean glass substrates and remove residues. RO-treated water ensures:

- Spot-free cleaning of glass surfaces.

- Elimination of particles that cause visual defects.

- Improved durability of displays.

4. Battery Manufacturing

Rechargeable batteries like lithium-ion require contamination-free water during electrode processing and assembly. RO water:

- Prevents chemical imbalances.

- Extends battery performance and lifespan.

5. Optical Devices and Microelectronics

In optics, even microscopic particles can ruin lenses or fiber optics. RO water ensures:

- Dust-free rinsing of optical lenses.

- Higher transmission efficiency in optical fibers.

Components of an Industrial RO Plant

To deliver ultra-pure water, industrial RO plants are designed with multiple stages of treatment. Let’s look at the essential components:

1. Pretreatment Systems

Before raw water enters the RO membrane, it undergoes pretreatment to remove larger impurities. This protects the delicate RO membranes from damage. Pretreatment may include:

- Sand filtration – removes suspended solids.

- Activated carbon filtration – removes chlorine and organics.

- Water softening – reduces hardness.

- Antiscalant dosing – prevents scale formation.

2. High-Pressure Pump

This pump provides the necessary force (200–1,200 psi) to push water through the semi-permeable membranes.

3. RO Membranes

The heart of the system. Thin-film composite membranes filter out contaminants as small as 0.0001 microns.

4. Post-Treatment Units

Even after RO, some additional polishing may be required:

- UV sterilizers – eliminate microbial contamination.

- Deionizers – remove residual ions for ultrapure water.

- Degassing units – remove dissolved gases like CO₂.

5. Automation and Control Systems

Modern RO plants come with advanced sensors and PLC-based controls that continuously monitor:

- Water conductivity and TDS levels.

- Pressure and flow rates.

- Membrane performance.

- Automatic backwashing and cleaning cycles.

Benefits of RO Plants for the Electronics Industry

- Unmatched Water Purity

- Removes up to 99.9% of dissolved solids, ions, and bacteria.

- Improved Product Quality

- Results in flawless wafers, PCBs, and semiconductors.

- Extended Equipment Life

- Prevents scaling and corrosion in production equipment.

- Regulatory Compliance

- Meets strict international standards for electronics water quality.

- Cost Efficiency

- Reduces rejection rates, chemical consumption, and maintenance costs.

- Sustainability

- Enables recycling and reuse of wastewater through integrated RO + ZLD systems.

Challenges in RO for Electronics Industry

While RO technology is highly effective, it comes with some challenges:

- High energy consumption for pumping at high pressures.

- Brine disposal issues that require proper management.

- Membrane fouling and scaling that demand regular cleaning.

- High initial investment in plant setup.

However, the long-term benefits in terms of product quality, reduced waste, and cost savings outweigh these challenges.

The Future of RO in Electronics Manufacturing

As electronics become smaller, faster, and more powerful, the demand for ultra-pure water will only increase. Future RO systems are expected to:

- Use energy-efficient membranes to reduce operational costs.

- Integrate with Zero Liquid Discharge (ZLD) systems for sustainability.

- Employ AI-driven monitoring systems for predictive maintenance.

- Deliver even higher purity levels to meet evolving semiconductor standards.

Conclusion

The electronics industry operates in a world of extreme precision where a single drop of impure water can cause million-dollar losses. Industrial RO plants provide the ultra-pure water that is the lifeline of semiconductor fabrication, PCB production, LCD manufacturing, and microelectronics assembly.

By eliminating impurities and ensuring consistent water quality, RO technology guarantees higher yields, better product quality, and compliance with global standards. As technology evolves, Industrial RO plants will remain at the heart of the electronics revolution.

So, the next time you use your smartphone, laptop, or TV, remember that behind the screen is a hidden hero—an Industrial RO Plant ensuring perfection in every electronic device.

📞 For customised Industrial RO Plants, Commercial RO systems, STPs, and ETP solutions, contact 3D AQUA:

- Phone: +91-6262629090

- Email: info@3daqua.in