Understanding the Role of an Aeration Tank in Water Treatment

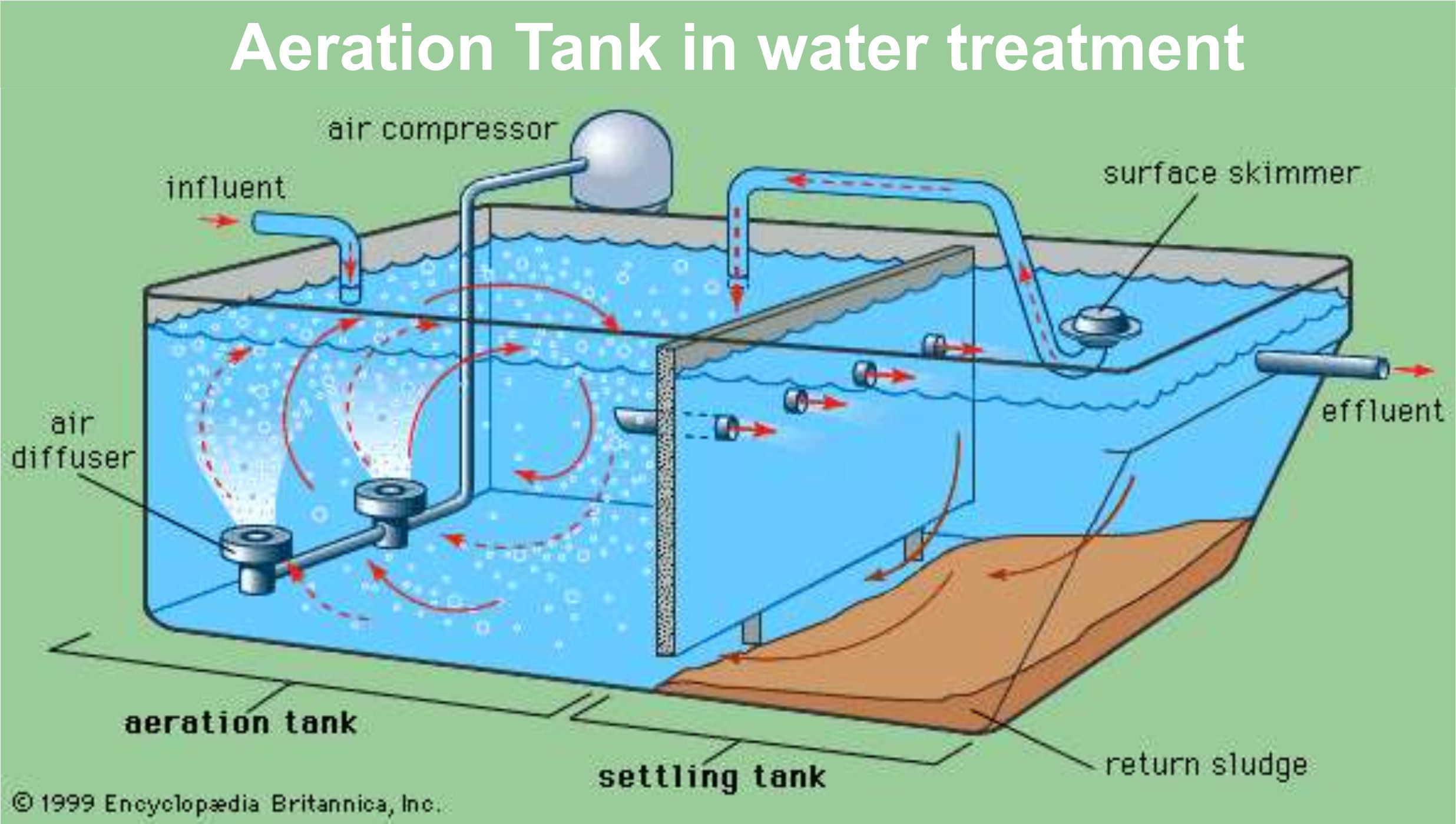

An aeration tank plays a crucial role in the biological treatment of wastewater. It facilitates the breakdown of contaminants using biomedia, which remains suspended in water and is continuously agitated through aeration.

Fine bubble diffusers, strategically placed at the tank’s bottom, supply oxygen to enhance microbial activity. This process supports biomass growth on the biomedia, effectively degrading pollutants and purifying the water.

To optimize performance, a baffle is installed near the tank’s inlet, ensuring proper settling and preventing sewage from bypassing the system too quickly.

Additionally, the inlet and outlet pipes are positioned at the farthest possible distance to maintain effective flow dynamics and retention time.

Where is Aeration Applied in the Tank?

Aeration occurs in cycles, allowing for both nitrification and denitrification processes. A freeboard of approximately seven feet is maintained within the tank to accommodate potential surges in sewage inflow.

The outlet of the tank is secured with a mesh to prevent the escape of biomedia, ensuring process efficiency and preventing operational disruptions.

Ensuring Maximum Retention Time in the Aeration Tank

To maximize the retention time of sewage in the aeration tank, wastewater from the raw sewage lift pump is directed through the inlet pipe, which originates from the equalization tank. The inlet pipe is designed with a downward bend to prevent direct flow into the outlet pipe, ensuring thorough treatment.

The presence of a baffle wall further aids in optimizing retention by directing the flow toward the tank’s bottom. This design enhances microbial interaction with pollutants, leading to effective treatment. The water level in the tank is maintained based on the launder’s top level, with the remaining height serving as a safety margin to prevent overflow under unexpected conditions.

Function and Location of the Outlet Launder

The outlet launder is responsible for collecting and transporting treated wastewater to the outlet pipe. Positioned at the farthest point from the inlet, it ensures that water undergoes complete treatment before exiting the tank.

A protective net prevents debris from entering the outlet pipe, reducing the risk of clogging. Operators must regularly clear accumulated debris from the launder to prevent blockages, which could lead to increased water levels and potential overflow in extreme cases.

The Outlet Pipe and Its Role in the Treatment Process

Once the aeration process is complete, the wastewater exits through the outlet pipe and is transported to the settling tank or secondary clarifier for further treatment. The aeration system uses fine bubble diffusers, consisting of rigid pipes with tubular synthetic rubber membranes. These membranes feature small perforations through which compressed air is released, creating fine bubbles that facilitate oxygen transfer and microbial activity.

Fixed diffusers, another common aeration system, distribute compressed air via a header pipe located at the tank’s base, ensuring efficient aeration throughout the tank.

Importance and Benefits of Aeration in Water Treatment

Aeration serves multiple essential functions in water treatment, including:

- Reduction of Volatile Organic Compounds (VOCs): Aeration significantly decreases the concentration of VOCs at the wastewater entry point, enhancing overall treatment effectiveness.

- Elimination of Dissolved Gases: Harmful gases such as hydrogen sulfide, methane, and radon are removed through aeration, improving water quality and reducing odors.

- Oxidation of Dissolved Iron: While aeration oxidizes dissolved iron, the resulting iron particles may require additional filtration to prevent system fouling.

- Enhanced Microbial Decomposition: The increased oxygen levels support microbial activity, leading to efficient degradation of organic matter and pollutants.

Why is Aeration Crucial for Sewage Treatment Plants?

Aeration is a fundamental process in sewage treatment plants (STPs) across various industries. It ensures that wastewater undergoes effective biological treatment before proceeding to further purification stages.

Without proper aeration, sewage treatment efficiency would be significantly compromised, leading to incomplete pollutant breakdown and environmental contamination.

Get Reliable STP Solutions from 3D Aqua Water Treatment Company

For industries seeking high-quality sewage treatment solutions, 3D Aqua Water Treatment Company is your trusted partner. Based in Noida, we are a leading manufacturer of water and wastewater treatment plants, offering:

- Commercial RO Plants

- Industrial RO Plants

- Sewage Treatment Plants (STPs)

- Water Softener Plants

- Effluent Treatment Plants (ETPs)

With a strong commitment to quality and customer satisfaction, we ensure top-tier solutions tailored to your needs. Our 24×7 customer support sets us apart, guaranteeing seamless operation and maintenance of your water treatment systems.

Contact Us Today! 📞 Call: +91-6262629090

📧 Email: info@3daqua.in

Visit our website to explore our range of water treatment solutions and get expert assistance for your specific requirements.

Choose 3D Aqua Water Treatment Company for superior water treatment solutions—efficiency, reliability, and sustainability at its best!