As global water demand increases and environmental regulations tighten, Membrane Bioreactor (MBR) technology is becoming the go-to solution for modern effluent treatment plants (ETPs). Combining conventional biological treatment with advanced membrane filtration, MBR offers a compact, efficient, and high-performance wastewater treatment process. It helps industries and municipalities achieve exceptional water quality, minimize environmental footprint, and support sustainable reuse practices.

One of the leading innovators in this space, 3D Aqua Water Treatment Company, is a trusted effluent treatment plant manufacturer that integrates cutting-edge MBR systems into its designs. Let’s dive deeper into the key benefits of using MBR technology in ETPs.

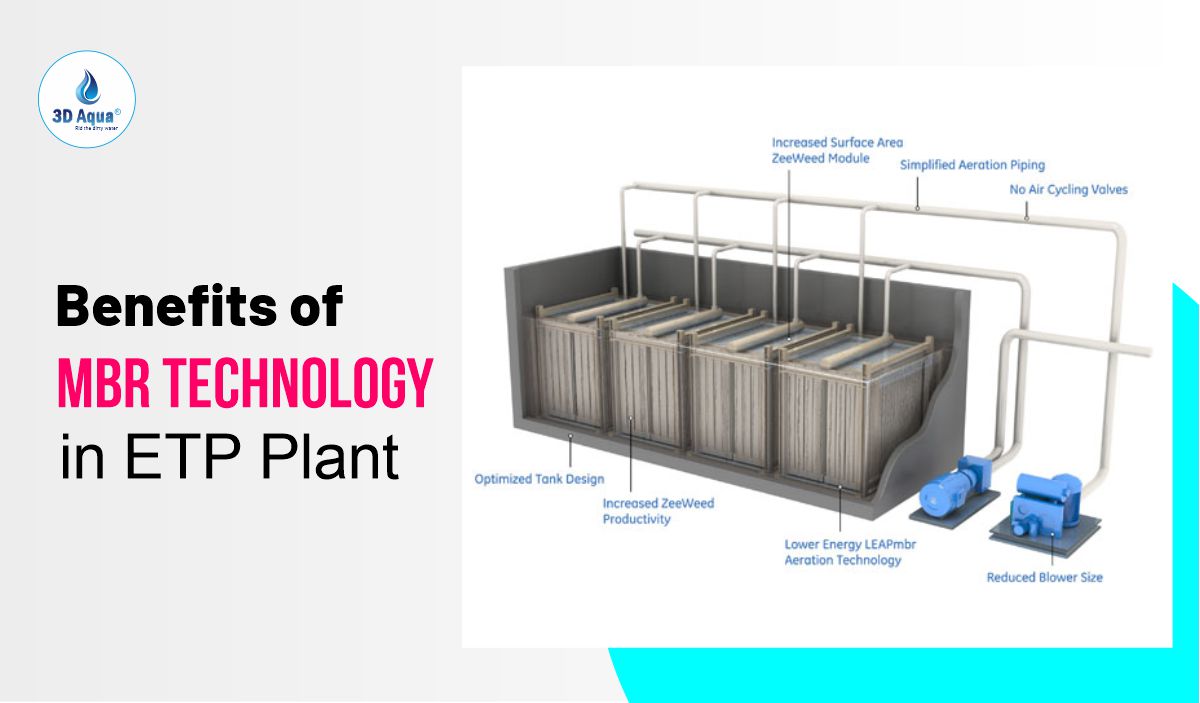

Top Benefits of MBR Technology in ETP

1. Superior Treated Water Quality

MBR systems deliver significantly higher effluent quality compared to traditional systems. They use ultrafiltration or microfiltration membranes to physically block suspended solids, bacteria, and pathogens from passing through. At the same time, biological processes break down organic compounds.

This dual mechanism allows MBRs to produce clear, odorless, and pathogen-free water that meets or exceeds regulatory discharge norms and is often suitable for reuse in non-potable applications like:

- Cooling towers

- Boiler feed

- Irrigation

- Floor washing

- Industrial processes

For industries aiming to achieve zero liquid discharge (ZLD), MBRs serve as a robust foundation before advanced polishing steps like reverse osmosis.

2. Compact Footprint and Design Flexibility

One of the major advantages of MBR systems is their space-saving design. Traditional activated sludge processes require large settling tanks for clarification. MBR eliminates the need for secondary clarifiers by integrating membrane modules that perform solid-liquid separation in the same tank.

This compact structure offers:

- Up to 50% space savings

- Simplified plant layouts

- Reduced civil construction costs

- Faster installation and commissioning

This makes MBR ideal for urban areas, retrofitting old plants, and industries with limited land availability. 3D Aqua Water Treatment Company designs modular MBR systems tailored to specific site conditions and client needs, ensuring maximum adaptability.

3. Operational Efficiency and Process Stability

MBR systems are engineered for stable, consistent, and automated performance. Their closed-loop, membrane-based design provides better control over retention times and biological activity, reducing the risks of upsets or process failures.

Key operational benefits include:

- Longer sludge retention time (SRT): Promotes effective biomass growth and enhances nutrient removal.

- Lower sludge production: Minimizes handling and disposal costs.

- Automation-ready systems: Supports remote monitoring and fewer manpower requirements.

- No dependency on sedimentation: Reduces treatment downtime due to poor settling.

This high level of reliability makes MBR systems a preferred choice in sensitive environments such as pharmaceutical, food processing, chemical, and textile industries.

4. Reduced Maintenance and Operating Costs

Although MBR systems may have a higher initial investment, they offer long-term savings through:

- Fewer mechanical parts, resulting in lower maintenance needs

- No need for flocculants or coagulants in solid-liquid separation

- Less frequent sludge removal due to low sludge yield

- Longer membrane lifespan with proper care and cleaning cycles

Membrane cleaning is automated and straightforward, and 3D Aqua ensures all MBR systems come with easy-to-follow maintenance protocols and full technical support.

5. Environmentally Sustainable Treatment

Sustainability is a core principle of modern water treatment. MBR systems contribute to this goal by:

- Enabling direct reuse of treated water

- Reducing land use and energy footprint

- Supporting zero discharge policies

- Minimizing chemical usage

With growing awareness of water conservation, 3D Aqua’s MBR solutions are helping industries lower their environmental impact and meet their corporate social responsibility (CSR) goals.

Why Choose 3D Aqua Water Treatment Company for MBR ETPs?

As one of the best effluent treatment plant manufacturers in India, 3D Aqua Water Treatment Company specializes in custom-designed MBR systems for a wide range of industrial and municipal applications. Our solutions are:

- Compact yet powerful

- Energy-efficient

- Easy to operate

- Designed for long-term durability

- Compliant with CPCB and SPCB norms

With in-house design expertise and a strong technical team, we ensure your MBR-based ETP performs at peak efficiency while offering peace of mind and environmental compliance.

Conclusion

Membrane Bioreactor (MBR) technology revolutionizes wastewater treatment with its unmatched efficiency, space-saving design, and exceptional water quality. By combining the best of biological and membrane filtration methods, MBRs empower treatment plants to operate reliably and sustainably.

Partnering with 3D Aqua Water Treatment Company ensures that your treatment plant is equipped with cutting-edge MBR solutions that are efficient, eco-friendly, and built to perform. Whether you’re upgrading an old system or installing a new ETP, MBR is the smart, future-ready choice.

Need help selecting the right MBR-based treatment system?

📞 Call us at +91-6262629090

📩 Email us at INFO@3DAQUA.IN

Our experts are ready to guide you with tailor-made water and wastewater solutions.