How to Choose Between MBBR and SBR Technology in STP Plants

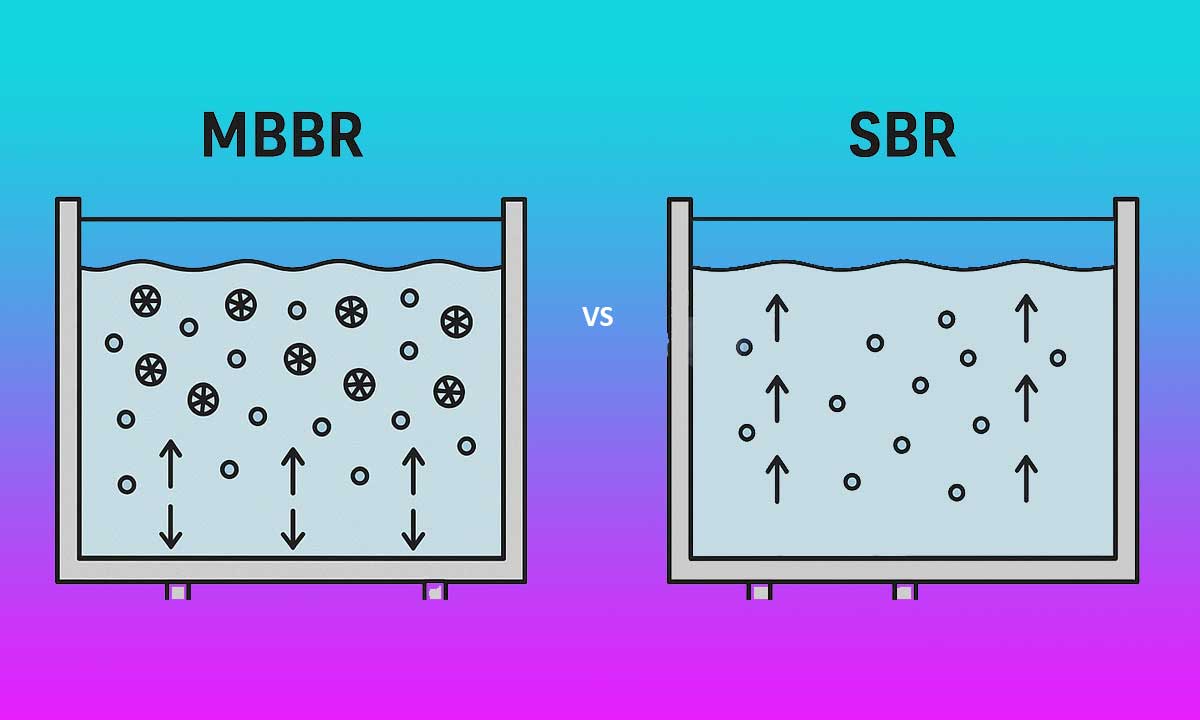

When it comes to efficient sewage treatment, two technologies have gained significant attention—MBBR (Moving Bed Biofilm Reactor) and SBR (Sequencing Batch Reactor). Each has its own strengths and is suitable for different scenarios, depending on your wastewater characteristics, operational preferences, and space availability.

In this guide, we will explore what MBBR and SBR technologies are, how they work, and the key differences that will help you make an informed choice for your Sewage Treatment Plant (STP).

Understanding the Basics of MBBR and SBR

What is MBBR Technology?

The Moving Bed Biofilm Reactor (MBBR) is an advanced biological treatment process that enhances the performance of traditional activated sludge systems. It uses specially designed plastic media or carriers that float in the aeration tank. These carriers provide a large surface area for microorganisms to grow and form biofilms, which break down organic matter in the sewage.

How it Works:

- Sewage enters the aeration tank.

- Air is pumped in to keep carriers in motion.

- Bacteria attached to the carriers degrade organic pollutants.

- After biological treatment, wastewater flows to a secondary clarifier for settling.

MBBR is a continuous flow system and does not rely on batch processing, making it ideal for systems with consistent inflow.

What is SBR Technology?

The Sequencing Batch Reactor (SBR) is a fill-and-draw activated sludge treatment process. It operates in a single tank where all treatment stages—filling, aeration, settling, and decanting—occur sequentially in time rather than space.

How it Works:

- Wastewater fills the tank during a controlled phase.

- Aeration encourages bacterial breakdown of pollutants.

- The system is then allowed to settle.

- Clear water is decanted, leaving behind sludge.

SBR technology is flexible and ideal for locations where influent flow varies widely throughout the day.

Key Differences Between MBBR and SBR Technologies

| Feature | MBBR | SBR |

|---|---|---|

| Treatment Mode | Continuous | Batch |

| Footprint | Compact | Larger footprint required |

| Maintenance | Low to moderate | Higher due to complex cycle controls |

| Nutrient Removal | Moderate | High (customizable through cycles) |

| Automation Needs | Low | High |

| Suitable for Variable Flow | Less suitable | Highly suitable |

| Operator Skill Level | Basic | Advanced |

| Expansion Potential | Modular and scalable | Complex |

Factors to Consider When Choosing Between MBBR and SBR

1. Available Space

If you’re short on land, MBBR has the advantage. Its compact and modular design fits easily into constrained urban or industrial spaces. On the other hand, SBR needs larger tank volumes because the same tank must perform multiple processes in different time cycles.

Best for limited space: MBBR

Best where space is not a constraint: SBR

2. Influent Characteristics and Flow Patterns

- MBBR is ideal for systems with steady, predictable inflow and organic load. It’s commonly used in hotels, residential complexes, and commercial spaces.

- SBR is well-suited for varying influent quality and quantity, such as municipal wastewater or industrial estates with peak flow hours.

For consistent flow: MBBR

For fluctuating flow: SBR

3. Treatment Objectives and Standards

If your treatment goals include nutrient removal (nitrogen and phosphorus), SBR offers better process control through customizable aerobic and anoxic cycles. While MBBR does provide good BOD and COD reduction, nutrient removal may need additional steps.

Best for strict discharge norms: SBR

Best for standard organic removal: MBBR

4. Operational Complexity and Automation

- SBR systems are heavily automated. They require programmable logic controllers (PLCs), timers, and actuated valves to handle batch sequencing.

- MBBR systems are simpler to operate, with minimal intervention required beyond aeration control and media management.

Best for simpler operations: MBBR

Best for advanced automation and control: SBR

5. Maintenance and Manpower

MBBR systems have fewer moving parts and don’t rely on cycle sequencing, making them easier and cheaper to maintain. SBR systems, while efficient, require skilled personnel for routine checks on timers, blowers, decanters, and control panels.

Low-maintenance choice: MBBR

Requires skilled operators: SBR

6. Capital and Operational Costs

Initial capital expenditure is often similar for both technologies. However, SBR might have slightly higher operational costs due to the use of complex control systems and higher energy consumption during aeration and decanting.

MBBR, with lower sludge production and simpler operation, can offer long-term cost benefits.

Pros and Cons of MBBR and SBR Technologies

✅ MBBR Advantages:

- Compact footprint – ideal for retrofitting in existing plants

- Easy to operate with minimal supervision

- Resistant to hydraulic and organic load fluctuations

- Low sludge generation

- Modular and easy to scale

❌ MBBR Limitations:

- Limited nutrient removal

- Requires an external clarifier

- Media may need replacement after several years

✅ SBR Advantages:

- Excellent nutrient removal (nitrogen and phosphorus)

- All treatment steps in a single tank

- Suitable for wide flow variations

- Highly customizable with automation

❌ SBR Limitations:

- Requires skilled operators

- High reliance on mechanical components

- Slightly larger space needed for equalization and storage tanks

Where Each Technology Works Best

| Sector/Industry | Recommended Technology |

|---|---|

| Hotels & Resorts | MBBR |

| Urban Housing | MBBR |

| Industrial Complexes | SBR |

| Municipal Corporations | SBR |

| IT Parks | MBBR |

| Educational Institutes | SBR |

Tips for Choosing the Right Technology

- Consult an Expert: Site evaluation by a qualified wastewater engineer will help determine the best-fit solution.

- Consider Future Growth: Choose scalable technology if you anticipate an increase in load.

- Analyze Local Regulations: Ensure your selected system can meet the discharge limits for your area.

- Account for Energy and Manpower: Operational costs and labor availability should be weighed in.

- Plan for Maintenance: Factor in ease of servicing, availability of parts, and downtime risks.

Conclusion

Both MBBR and SBR technologies are robust, modern wastewater treatment methods with proven track records in India and around the globe. The choice depends entirely on your specific project needs—space, flow patterns, treatment goals, and operational resources.

If you’re looking for simplicity, compactness, and cost-effectiveness, MBBR is likely your best bet. However, if you need advanced nutrient removal, flexible operation, and are equipped for automation, SBR might be the superior option.

By understanding the strengths and limitations of each system, you’ll be empowered to make a well-informed, strategic investment in your sewage treatment plant.

Need help selecting the right technology for your STP?

We at 3D Aqua offer end-to-end consulting, design, and installation services for all types of water and wastewater treatment plants. Whether it’s MBBR, SBR, or a hybrid solution, our team will help you find the ideal technology tailored to your project needs.

📞 Call us: +91-6262629090

📧 Email: info@3daqua.in

Let’s create a sustainable future—one drop at a time.