Industrial Ultrafiltration Systems – Advanced Water Treatment

Original price was: ₹250,000.00.₹210,000.00Current price is: ₹210,000.00.

Ultra Filtration (UF) System Manufacturer in Delhi/NCR

| Membrane Material | : Hydrophilic |

| Max Operating Temperature | : 45OC |

| Recovery | : 90-95% |

| CIP Operating pH | : 2-9 |

| Flow Type | : Out To In |

We are a certified company with over 20 years of experience, committed to customer satisfaction.

Description

In today’s rapidly growing industrial landscape, water treatment has become a critical focus for businesses looking to ensure high-quality production processes, maintain operational efficiency, and comply with stringent environmental standards. Among the various methods available, Ultrafiltration (UF) has emerged as one of the most effective and reliable technologies for water purification. This article delves into the importance, functionality, and industrial applications of Ultrafiltration systems, highlighting their role in water treatment and purification across various industries.

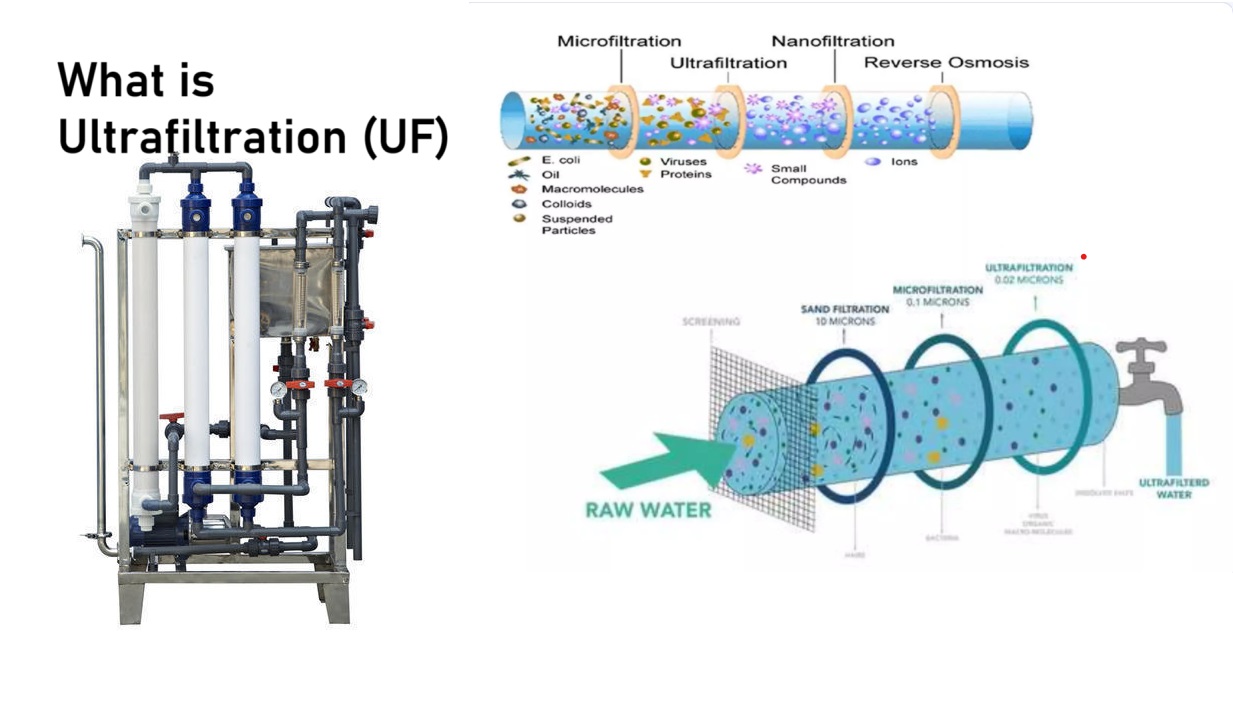

What is Ultrafiltration?

Ultrafiltration is a membrane filtration technique that uses pressure to force water through a semi-permeable membrane. This process effectively separates particles, solutes, and contaminants from liquids, ensuring that only pure water passes through the membrane. The UF membrane’s pores are typically between 0.01 to 0.1 microns, which allows the filtration of bacteria, viruses, and suspended solids while permitting smaller molecules, such as water and low-molecular-weight solutes, to pass through.

The semi-permeable membranes used in UF are usually made from polymer materials, including polyethersulfone, polyvinylidene fluoride (PVDF), or polysulfone. Under pressure, the water is forced through the membrane, trapping larger particles like suspended solids, germs, and viruses. The treated water, now free of contaminants, is collected for further use.

Importance of Ultrafiltration Systems

Ultrafiltration systems play a significant role in water treatment, offering a variety of benefits to industries that require clean water for their processes. The importance of these systems can be summarized by the following key points:

1. Removal of Contaminants

Ultrafiltration effectively removes a wide range of contaminants from water. The small pores in the UF membranes enable them to filter out bacteria, viruses, and suspended particles, ensuring that the water is free from harmful pathogens. UF is particularly effective for contaminants that range in size from 0.01 to 0.1 microns, which include organic material, colloidal particles, and certain microorganisms.

2. Improves Water Quality

By removing pollutants, toxins, and contaminants, UF improves the overall quality of water. Contaminants that affect the taste, odor, and purity of water are effectively removed, providing safe and clean water for consumption or industrial use. The process also ensures that the water is free from harmful bacteria and viruses, which can otherwise lead to health risks.

3. Reduces Chemical Usage

In many traditional water treatment methods, chemicals such as chlorine or other disinfectants are often added to kill bacteria or viruses. However, ultrafiltration can significantly reduce or even eliminate the need for these chemicals. This not only lowers the overall cost of water treatment but also reduces the negative environmental impacts associated with chemical usage.

4. Energy-Efficiency

Ultrafiltration is a relatively energy-efficient process compared to other water treatment methods like reverse osmosis (RO). Since it operates at lower pressures and requires less energy for operation, UF is an attractive option for industries aiming to reduce their energy consumption and associated operational costs.

5. Pre-Treatment for Reverse Osmosis

Ultrafiltration is often used as a pre-treatment step before reverse osmosis (RO) or other water purification methods. The UF process effectively removes large particles and impurities, ensuring that the subsequent RO process can operate more efficiently and last longer.

Types of Ultrafiltration Systems

There are several different types of ultrafiltration systems based on the flow pattern and application. The two most commonly used flow configurations are dead-end filtration and cross-flow filtration.

1. Dead-End Filtration

In dead-end filtration, the feedwater flows directly into the membrane surface, and the filtered water passes through the membrane while the contaminants accumulate on the membrane’s surface. This configuration is suitable for applications where the water has low to moderate contamination and a low flow rate.

2. Cross-Flow Filtration

Cross-flow filtration involves the feedwater flowing tangentially across the membrane’s surface. The contaminated water passes along the membrane, and the filtered water permeates through it, allowing the contaminants to be continuously flushed away. Cross-flow filtration is ideal for handling high volumes of water with moderate to high contamination levels and is more commonly used in industrial applications.

Industrial Applications of Ultrafiltration Systems

Ultrafiltration systems are used in various industries for water purification and treatment. Below are some key industrial sectors that benefit from UF technology:

1. Food and Beverage Industry

In the food and beverage industry, maintaining high-quality water is crucial for product safety and taste. Ultrafiltration is used to purify water and remove contaminants like bacteria, viruses, and suspended particles. UF is also employed for the concentration and purification of food items such as milk, whey, fruit juices, and other beverages. The ability to remove contaminants without altering the flavor or nutritional content of these products makes UF an essential technology in food and beverage manufacturing.

2. Pharmaceutical Industry

The pharmaceutical industry requires extremely clean water for the production of medicines, vaccines, and other healthcare products. Ultrafiltration plays a key role in purifying water used in pharmaceutical manufacturing. It removes endotoxins, bacteria, and other contaminants, ensuring that the water meets the stringent purity standards required for the production of pharmaceutical products.

3. Chemical Industry

The chemical industry uses UF systems to purify and separate various compounds, such as solvents, polymers, and chemicals. UF also plays a critical role in the treatment of industrial wastewater, removing harmful pollutants and making it safe for discharge or reuse. This helps industries comply with environmental regulations and reduce their overall environmental footprint.

4. Textile Industry

In the textile industry, water is used extensively during the dyeing and finishing processes. Ultrafiltration systems help remove dyes, pigments, and other contaminants from the water used in these processes. By doing so, UF systems help recycle water, reduce waste, and minimize the environmental impact of textile manufacturing.

5. Electronics Manufacturing

Water used in the electronics industry needs to be free of contaminants to ensure the proper functioning of sensitive components. Ultrafiltration systems are employed to purify water used in cleaning and rinsing processes during electronics manufacturing. The removal of bacteria, particulate matter, and chemicals ensures the production of high-quality electronics with fewer defects.

6. Oil and Gas Industry

In the oil and gas industry, ultrafiltration is used to treat water used in drilling and refining processes. UF helps remove contaminants such as suspended solids, oil, and other impurities, ensuring that the water is safe for reuse or discharge, thereby reducing operational costs and protecting the environment.

Ultrafiltration in Water Treatment: Principles and Processes

The principle of ultrafiltration is based on membrane filtration, where water is forced through a semi-permeable membrane under pressure. The size of the pores in the membrane is crucial in determining the type of contaminants it can filter out. While UF membranes remove contaminants as small as 0.01 microns, they allow dissolved salts, low-molecular-weight substances, and water to pass through.

The pressure applied to the feedwater forces it against the membrane, causing smaller particles and solutes to pass through while larger molecules like bacteria, viruses, and suspended solids are trapped on the membrane surface. The process is continuous, and filtered water is collected as permeate, while the trapped contaminants are flushed away as concentrate.

Key Features of Ultrafiltration Systems

- Membrane Material: Typically made from hydrophilic polymer materials like polyethersulfone and polyvinylidene fluoride (PVDF).

- Max Operating Temperature: Typically around 45°C, which ensures that the system can handle a wide range of industrial applications.

- Recovery Rate: Ultrafiltration systems typically offer a 90-95% recovery rate, meaning a large portion of the feedwater is converted into clean, usable water.

- CIP (Cleaning-in-Place) Operating pH: The systems are designed to handle pH levels between 2 to 9, making them highly adaptable to different water sources and treatment requirements.

Conclusion

Ultrafiltration systems represent a key technology in industrial water treatment, offering effective filtration, low energy consumption, and minimal environmental impact. From the food and beverage industry to pharmaceuticals and chemical manufacturing, these systems play a critical role in providing clean, high-quality water for industrial processes.

The ability of ultrafiltration to remove a wide range of contaminants while reducing the need for chemicals makes it an invaluable asset to industries seeking to improve water quality, reduce operational costs, and meet environmental regulations. As water scarcity continues to be a pressing concern globally, ultrafiltration systems will continue to play a central role in sustainable water treatment practices.

Whether you’re seeking to upgrade your industrial water treatment system or invest in a new solution, ultrafiltration technology offers the reliability, efficiency, and performance you need to meet the growing demands of industrial water treatment.

Reviews

There are no reviews yet.