The proper treatment of sewage is one of the most crucial aspects of urban infrastructure and environmental protection. Without an effective system in place, untreated wastewater can pose severe threats to public health, aquatic life, and natural ecosystems. A Sewage Treatment Plant (STP) is designed to process and treat domestic and industrial wastewater, making it safe for reuse or discharge into the environment. In this article, we provide a complete breakdown of the sewage treatment plant process, accompanied by a practical process flow diagram for easier understanding.

1. What is Sewage?

Sewage is wastewater that originates from households, commercial buildings, hospitals, and industries. It contains organic and inorganic matter, including:

- Human waste

- Food particles

- Detergents and chemicals

- Pathogens (bacteria, viruses)

- Oils and greases

- Plastics and suspended solids

If released untreated, sewage can contaminate water bodies and soil, spreading disease and damaging ecosystems.

2. What is a Sewage Treatment Plant?

A Sewage Treatment Plant (STP) is a facility that treats wastewater and converts it into clean effluent that can be safely discharged or reused. The process involves physical, chemical, and biological methods to remove contaminants from the wastewater.

Depending on the size and application, STPs are installed in:

- Residential societies

- Commercial buildings

- Hospitals

- Industries

- Hotels and resorts

- Municipal infrastructure

3. Importance of Sewage Treatment

Here’s why sewage treatment is essential:

- ✅ Prevents water pollution in rivers, lakes, and groundwater

- ✅ Controls the spread of waterborne diseases

- ✅ Supports water recycling and conservation

- ✅ Complies with environmental regulations (CPCB, SPCB norms)

- ✅ Reduces ecological and human health hazards

4. Step-by-Step Process of STP (With Flow Diagram)

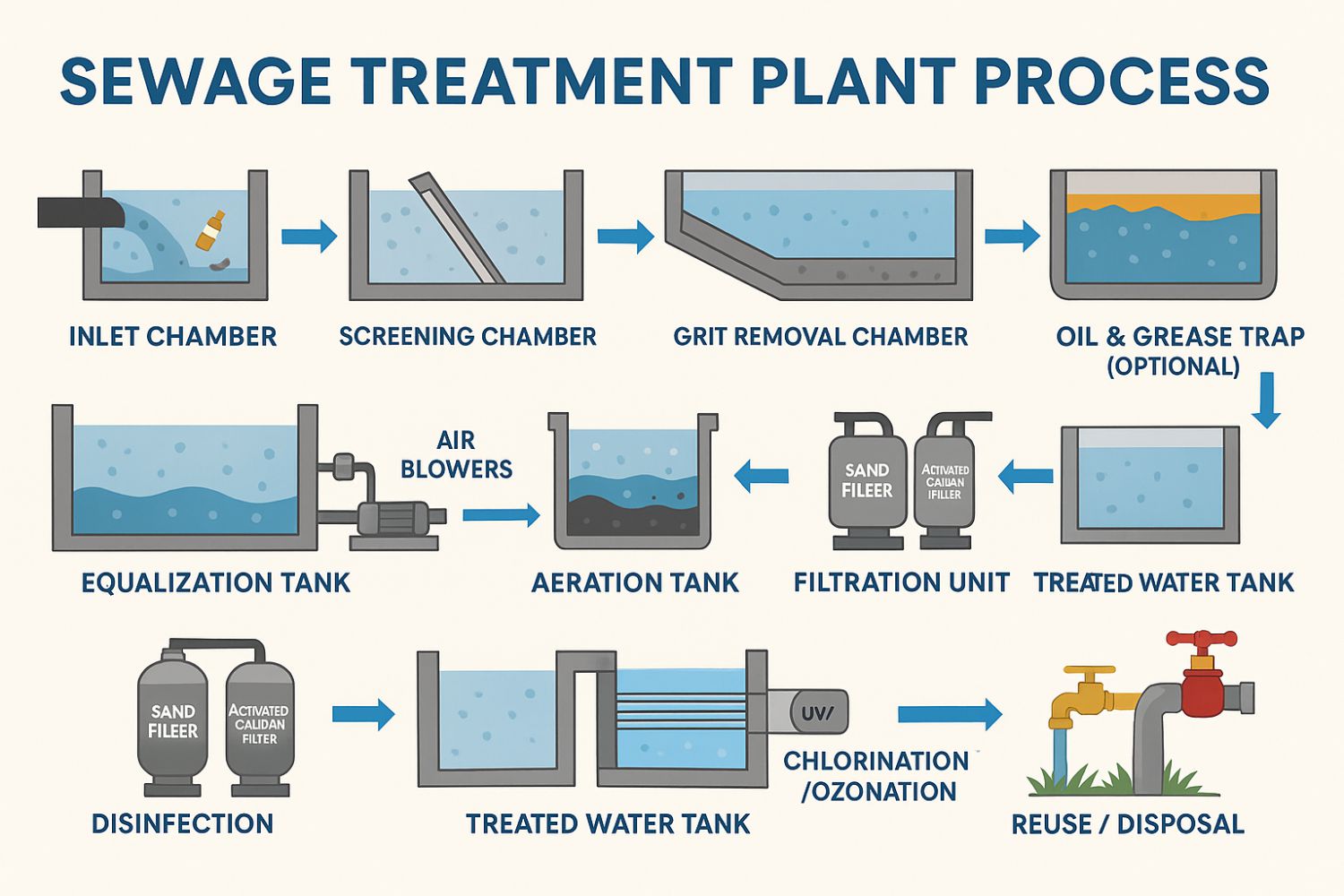

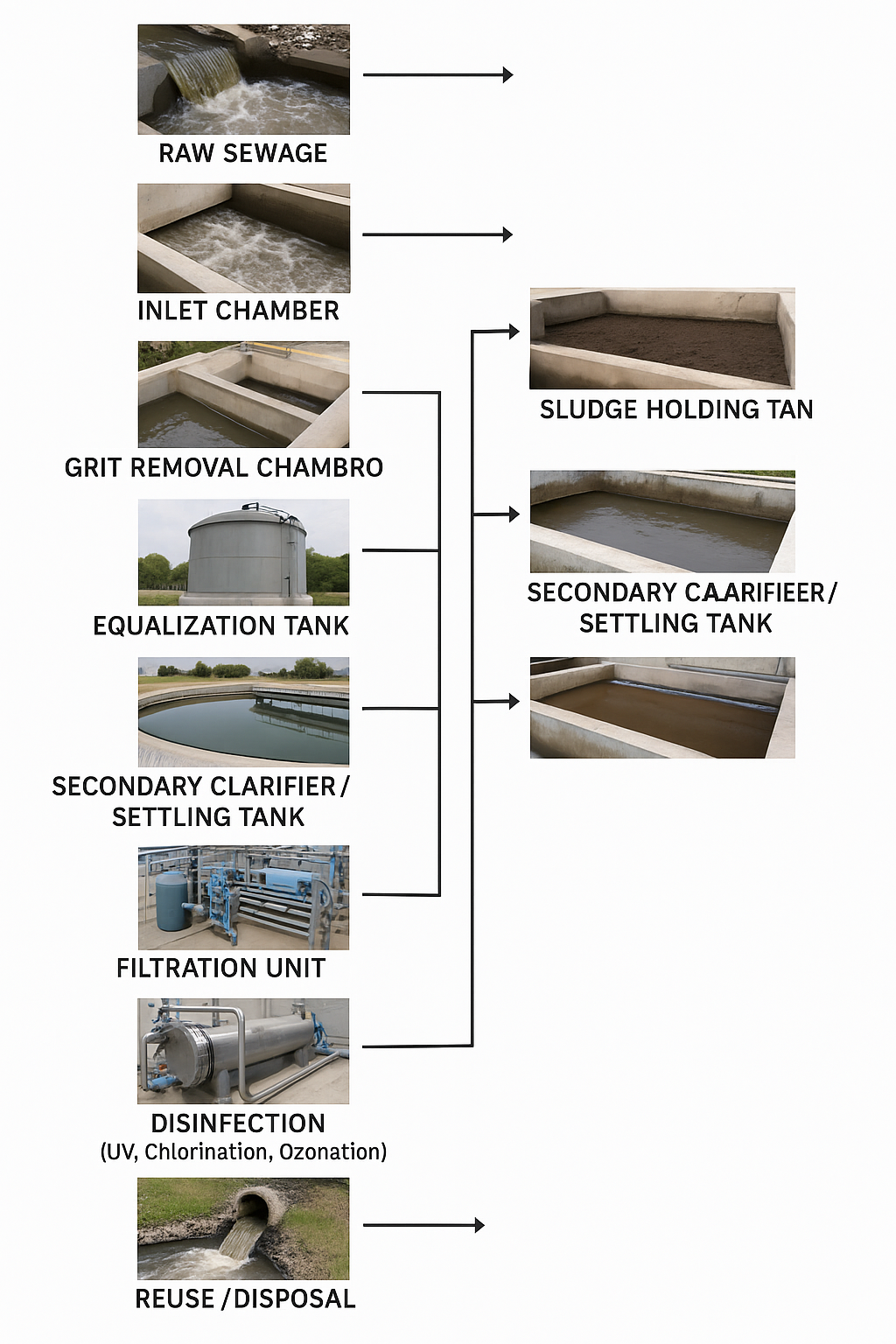

Let’s understand the typical Sewage Treatment Plant Process Flow, as illustrated in the diagram above. This process ensures the systematic removal of pollutants from raw sewage.

🔶 1. Inlet Chamber

Purpose: To receive the raw sewage from domestic or industrial pipelines.

- Acts as the entry point for all wastewater.

- Often equipped with a grit channel or flow meter.

- Flow balancing starts here.

🔶 2. Screening Chamber

Purpose: To remove large floating objects.

- Installed with bar screens or mechanical screeners.

- Captures plastics, rags, wood, and debris.

- Protects downstream equipment from clogging.

🔶 3. Grit Removal Chamber

Purpose: To remove heavy solids like sand, gravel, and silt.

- Works via sedimentation.

- Prevents abrasion and wear in pumps and pipes.

- Usually installed after screening.

🔶 4. Oil & Grease Trap (Optional)

Purpose: To capture fats, oils, and grease (FOG).

- Especially useful in STPs for hotels, kitchens, and food processing units.

- Prevents clogging of downstream pipelines.

- Uses a compartmentalized chamber to allow oils to float and be skimmed off.

🔶 5. Equalization Tank

Purpose: To balance the flow and load of sewage.

- Maintains consistent flow rate and quality.

- Equipped with air blowers to prevent septic conditions.

- Acts as a buffer between pretreatment and biological treatment.

🔶 6. Aeration Tank (Biological Treatment)

Purpose: To degrade organic matter using microorganisms.

Common technologies:

- Activated Sludge Process (ASP)

- MBBR (Moving Bed Biofilm Reactor)

- SBR (Sequential Batch Reactor)

- MBR (Membrane Bio-Reactor)

Aeration is done by blowers to supply oxygen, helping aerobic bacteria break down organic pollutants.

🔶 7. Secondary Clarifier (Settling Tank)

Purpose: To settle out biological sludge from treated water.

- Works on the gravity principle.

- Clear water flows to the next stage; sludge is pumped back (return activated sludge – RAS) or sent to sludge handling.

🔶 8. Filtration Unit

Purpose: To remove suspended solids and improve clarity.

Typically consists of:

- Pressure Sand Filter (PSF): Removes fine particles.

- Activated Carbon Filter (ACF): Removes odor, color, and organics.

Ensures water is aesthetically and chemically clean.

🔶 9. Disinfection Unit

Purpose: To kill pathogens and make the water safe.

Disinfection options:

- Chlorination

- UV Sterilization

- Ozonation

Prepares water for reuse or safe discharge.

🔶 10. Treated Water Outlet

Purpose: Clean water is now safe for:

- Gardening and landscaping

- Flushing

- Cooling towers

- Irrigation

- Discharge into water bodies (with permission)

5. Sludge Management

The biological treatment process produces sludge, which needs proper handling.

Sludge Line Includes:

- Sludge Holding Tank: Temporarily stores sludge from clarifiers.

- Sludge Dewatering Unit: Removes water content using filter press or centrifuge.

- Dry Sludge Disposal: Can be used as compost, fuel, or disposed of in landfills.

Efficient sludge treatment reduces volume and facilitates safe disposal.

6. Treated Water Reuse Options

Properly treated water from an STP can be reused in several ways:

| Reuse Application | Benefits |

|---|---|

| Flushing Toilets | Saves freshwater use |

| Garden Irrigation | Promotes greenery |

| HVAC Cooling Towers | Reduces municipal water dependency |

| Construction Use | Ideal for curing and site activities |

| Vehicle Washing | Economical and sustainable |

7. Advanced Technologies in STPs

Modern STPs use automation, sensors, and energy-efficient designs:

- SCADA-based automation for real-time monitoring

- Membrane-based filtration (UF, NF)

- Energy-efficient blowers and pumps

- Compact STP Designs for basement or rooftop installations

- IoT and AI integration for performance optimization

8. Benefits of Efficient STP Operation

✅ Meets pollution control norms

✅ Reduces water bills through recycling

✅ Enhances corporate environmental responsibility

✅ Supports green building certification (LEED, IGBC)

✅ Protects groundwater and local water bodies

9. Common Challenges and Solutions

| Challenge | Solution |

|---|---|

| High maintenance cost | Use energy-efficient equipment |

| Inconsistent flow or shock loads | Equalization tank and smart control systems |

| Odor and noise | Enclosed tanks, biofilters, silencers |

| Space limitations | Use modular or compact STPs |

| Lack of skilled manpower | Automation and periodic training |

10. Conclusion

Sewage treatment is not just a regulatory necessity—it is a civic responsibility and an environmental safeguard. A properly designed and maintained STP ensures clean water, healthier communities, and a sustainable future. From the inlet chamber to disinfection, each stage in the sewage treatment plant plays a critical role in ensuring safe water reuse and reducing environmental pollution.

Whether you’re a builder, facility manager, municipal authority, or industrial operator, investing in a robust STP system is both a wise decision and a regulatory obligation.

📌 3D Aqua: India’s Leading STP Manufacturer

If you’re looking for reliable, CPCB-compliant, and affordable STP systems, 3D AQUA is your trusted partner. We manufacture MBBR, SBR, and MBR STPs with capacities ranging from 1 KLD to 1 MLD, tailored for your commercial or residential needs.

📩 Email: info@3daqua.in

📞 Phone: 626262 9090

🌐 Visit: www.3daqua.in