Sewage Treatment Plant (STP Plant) Manufacturer in Small and Big Delhi: 3D Aqua Water Treatment Company – Best Quality and 100% Satisfaction

Introduction

In today’s world, effective wastewater management is crucial for both environmental sustainability and public health. One of the key players in this sector is the Sewage Treatment Plant (STP), which is designed to treat and purify wastewater before it is released back into the environment or reused. Among the leading manufacturers of STP plants in Delhi is 3D Aqua Water Treatment Company.

Known for its commitment to high-quality products and exceptional customer service, 3D Aqua stands out as the premier choice for STP solutions in India.

In this comprehensive article, we will delve into what sets 3D Aqua Water Treatment Company apart as the best STP plant manufacturer in Delhi, the factors that contribute to their 100% satisfaction guarantee, and the significant impact their technology has on wastewater management.

Understanding STP Plants

What is an STP Plant?

A Sewage Treatment Plant (STP) is a facility designed to process and treat wastewater from various sources, including residential, commercial, and industrial areas. The primary goal of an STP is to remove contaminants and pollutants from wastewater to make it safe for discharge into the environment or for reuse.

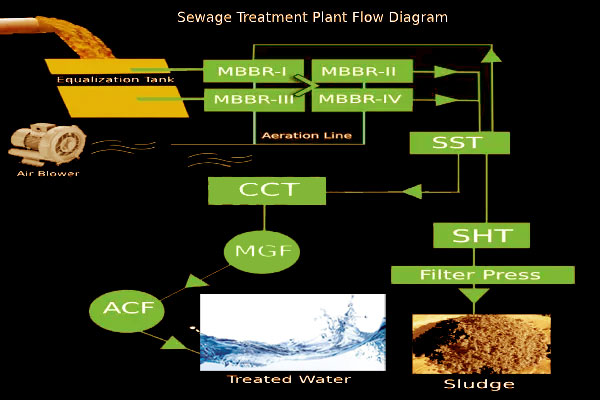

How Does an STP Plant Work?

An STP plant typically involves several stages of treatment:

- Pre-Treatment: This stage involves the removal of large solids and debris from the wastewater. It often includes screening and grit removal processes.

- Primary Treatment: In this phase, the wastewater is settled in a tank, allowing heavier solids to settle at the bottom, forming sludge, while lighter materials float to the surface.

- Secondary Treatment: This is the biological treatment phase where microorganisms break down organic pollutants in the wastewater. Methods like activated sludge, trickling filters, or bio-towers are commonly used.

- Tertiary Treatment: The final stage involves additional filtration and disinfection to remove any remaining contaminants and ensure the treated water meets regulatory standards.

- Sludge Treatment: The sludge accumulated during the treatment process is further processed to reduce its volume and make it safe for disposal or reuse.

Advanced Technologies in Sewage Treatment Plants

1. Extended Aeration (EA) Systems

Extended Aeration (EA) Sewage Treatment Plants offer an eco-friendly approach to wastewater management. These systems utilize extended aeration to support the growth of beneficial microorganisms that effectively decompose organic waste. EA STP plants are recognized for their energy efficiency and minimal environmental impact, making them a pivotal technology in the pursuit of cleaner waterways.

2. Submerged Aerated Fixed Film (SAFF) Technology

Submerged Aerated Fixed Film (SAFF) Sewage Treatment Plants are advanced systems that integrate fixed film media with aeration processes. This combination fosters the growth of beneficial bacteria that break down pollutants. SAFF STP plants are celebrated for their high efficiency, low energy consumption, and significant contributions to environmental sustainability.

3. Sequential Batch Reactor (SBR) Systems

The Sequential Batch Reactor (SBR) Sewage Treatment Plant operates in a cyclic batch mode, making it a versatile solution for wastewater treatment. By alternating between aeration and settling phases, SBR STP plants effectively remove contaminants. They are valued for their adaptability, reduced energy use, and efficient treatment processes, contributing to a greener environment.

4. Moving Bed Bio-Reactor (MBBR) Technology

Moving Bed Bio-Reactor (MBBR) Sewage Treatment Plants employ suspended plastic media to create an ideal surface for microorganisms to thrive. This advanced method provides a compact, high-efficiency solution capable of handling varying wastewater loads. MBBR STP plants are known for their space-saving design and sustainability in water treatment.

5. Membrane Bio-Reactor (MBR) Systems

Membrane Bio-Reactor (MBR) Sewage Treatment Plants combine biological treatment with membrane filtration to achieve superior wastewater purification. MBR technology is acclaimed for producing high-quality treated water, compact system design, and its contribution to environmental sustainability. This cutting-edge method plays a crucial role in advanced sewage treatment.

Compact Sewage Treatment Plants: An Overview

Compact Sewage Treatment Plants

Compact Sewage Treatment Plants are designed to maximize efficiency in a minimal space, making them ideal for various applications. 3D AQUA, a leading manufacturer in India, offers compact systems that cater to different capacities, ranging from 1KLD to 10MLD. These plants are designed for easy installation and high return on investment (ROI), effectively treating wastewater while conserving water resources.

Advantages of Compact Sewage Treatment Plants

- High ROI: These systems offer a substantial return on investment by efficiently treating wastewater and saving water.

- Efficient Water Utilization: Compact STPs ensure optimal use of water resources.

- Low Maintenance Costs: Designed for minimal upkeep, reducing overall operational costs.

- Affordable Operation: Operating costs are kept low, making them a cost-effective solution.

- Effective Cleaning: Ensures high standards of wastewater treatment and cleanliness.

Applications of Sewage Treatment Plants Across Industries

1. Agricultural Sector

Sewage Treatment Plants are vital in the agricultural industry, processing farm wastewater to remove pollutants and pathogens. The treated water can be reused for irrigation, promoting water conservation and sustainable farming practices.

2. Oil & Mining Industry

In the Oil & Mining sector, STPs handle wastewater from extraction and processing activities. These plants ensure environmental protection by treating contaminants and meeting strict regulatory standards for water discharge and reuse.

3. Hospitality Industry

Hotels and resorts use Sewage Treatment Plants to manage wastewater from guest facilities and kitchens. These systems help in maintaining environmental responsibility by treating and safely disposing of or reusing wastewater.

4. Manufacturing Sector

The Manufacturing Industry relies on STPs to treat industrial wastewater, removing chemicals and contaminants. This practice helps in adhering to environmental regulations and supports sustainable manufacturing practices.

5. Residential Communities

In residential societies, STPs are used to treat household wastewater, allowing for water recycling and reducing environmental impact. These plants contribute to cleaner surroundings and promote sustainable living.

6. Aviation Sector

Airports and aviation facilities use Sewage Treatment Plants to manage wastewater generated by aircraft and terminal operations. These systems ensure eco-friendly disposal and align with the industry’s sustainability goals.

7. Fast-Moving Consumer Goods (FMCG)

FMCG companies utilize STPs to handle wastewater from their production processes. These plants help in maintaining compliance with environmental regulations and minimizing ecological impact.

8. Automobile Industry

Sewage Treatment Plants in the Automobile Industry process wastewater from manufacturing, removing contaminants and oils. They support compliance with environmental standards and promote eco-friendly practices.

9. Educational Institutions

Educational institutions use STPs to manage wastewater from campuses, promoting environmental responsibility. These systems help reduce ecological footprints and demonstrate a commitment to sustainability.

Compact Effluent Treatment Plants by 3D Aqua

3D Aqua also offers Compact Effluent Treatment Plants that function similarly to Sewage Treatment Plants in managing wastewater. Known for their efficiency and reliability, these plants are a testament to 3D Aqua’s commitment to advanced and effective water treatment solutions. For top-notch machines and technology, trust the brand that many rely on for their wastewater treatment needs.

3D Aqua Water Treatment Company: An Overview

Company Background

3D Aqua Water Treatment Company has established itself as a leading manufacturer of STP plants in Delhi, India. With years of experience in the water treatment industry, the company is renowned for its innovative solutions and commitment to excellence. Their expertise covers a wide range of water and wastewater treatment solutions, including STP plants, water recycling systems, and effluent treatment plants.

Why 3D Aqua Stands Out

1. Cutting-Edge Technology

3D Aqua employs the latest technology and advancements in wastewater treatment to ensure that their STP plants are efficient, reliable, and compliant with the highest standards. Their systems incorporate state-of-the-art components and processes, which are continuously updated to reflect the latest industry innovations.

2. Custom Solutions

Understanding that each project has unique requirements, 3D Aqua offers customized solutions tailored to the specific needs of their clients. Whether it’s a small residential STP or a large industrial plant, they provide bespoke designs that maximize efficiency and performance.

3. Quality Assurance

Quality is a cornerstone of 3D Aqua’s operations. The company adheres to rigorous quality control procedures at every stage of the manufacturing process. From sourcing high-grade materials to final product testing, they ensure that every STP plant meets international quality standards.

4. Experienced Team

The success of 3D Aqua is largely attributed to its skilled and experienced team of engineers, technicians, and support staff. Their collective expertise ensures that each project is executed with precision and attention to detail.

5. Customer-Centric Approach

3D Aqua places a strong emphasis on customer satisfaction. They work closely with clients to understand their needs and provide comprehensive support throughout the project lifecycle. Their customer service team is readily available to address any queries or concerns, ensuring a smooth and hassle-free experience.

The Process of Acquiring an STP Plant from 3D Aqua

Initial Consultation

The journey begins with an initial consultation where the 3D Aqua team discusses the project requirements with the client. This includes understanding the scope of the project, the volume of wastewater to be treated, and any specific needs or preferences.

Design and Proposal

Based on the consultation, 3D Aqua’s engineering team designs a customized STP plant solution. A detailed proposal is provided, outlining the design specifications, technology to be used, and the project timeline. This proposal ensures transparency and helps clients make informed decisions.

Manufacturing and Installation

Once the proposal is approved, the manufacturing process begins. 3D Aqua’s state-of-the-art facilities produce high-quality components that are then assembled into the final STP plant. The installation is carried out by skilled technicians who ensure that the plant is set up efficiently and according to the design specifications.

Testing and Commissioning

Before the plant becomes operational, it undergoes rigorous testing to ensure it performs as expected. This includes testing for efficiency, reliability, and compliance with regulatory standards. Once testing is complete, the plant is commissioned and handed over to the client.

Ongoing Support and Maintenance

3D Aqua offers comprehensive support and maintenance services to ensure the continued performance of their STP plants. Regular maintenance checks, prompt repairs, and upgrades are part of their commitment to keeping the plant running smoothly.

Case Studies: Successful Projects by 3D Aqua

Residential Complex in Delhi

One of the notable projects undertaken by 3D Aqua was the installation of an STP plant for a large residential complex in Delhi. The project required a solution capable of handling the wastewater from hundreds of apartments. 3D Aqua designed a compact, high-efficiency STP plant that met the complex’s needs while adhering to environmental regulations. The plant has been operating smoothly, providing reliable wastewater treatment and contributing to the complex’s sustainability goals.

Industrial Facility in NCR

For an industrial facility in the Delhi/NCR region, 3D Aqua developed a robust STP plant designed to manage high volumes of wastewater with significant pollutant loads. The custom solution included advanced treatment technologies and a sophisticated control system to ensure optimal performance. The plant has been instrumental in helping the facility maintain compliance with industrial wastewater regulations and achieve its environmental objectives.

The Impact of 3D Aqua’s STP Plants

Environmental Benefits

The STP plants manufactured by 3D Aqua play a crucial role in protecting the environment. By effectively treating wastewater, these plants prevent the release of harmful pollutants into natural water bodies, thus safeguarding aquatic ecosystems and reducing water pollution.

Public Health

Properly treated wastewater is essential for public health. 3D Aqua’s STP plants ensure that wastewater is treated to a standard that minimizes health risks associated with untreated sewage, contributing to a healthier community.

Resource Conservation

In addition to treating wastewater, some of 3D Aqua’s STP plants are designed to facilitate water recycling and reuse. This helps conserve valuable water resources and supports sustainable practices.

Compliance and Regulation

Adhering to local and national regulations is critical for wastewater treatment facilities. 3D Aqua’s STP plants are designed to meet or exceed regulatory requirements, ensuring that clients remain compliant with environmental laws and standards.

Why Choose 3D Aqua Water Treatment Company?

Expertise and Experience

With a wealth of experience in the water treatment industry, 3D Aqua is well-equipped to handle a wide range of STP projects. Their expertise ensures that clients receive high-quality solutions that are both effective and reliable.

Commitment to Quality

3D Aqua’s dedication to quality is evident in every aspect of their operations. From design and manufacturing to installation and maintenance, they prioritize excellence and customer satisfaction.

Innovative Solutions

The company’s use of cutting-edge technology and innovative solutions sets them apart from competitors. Their STP plants are designed to deliver superior performance and efficiency.

Customer Satisfaction

3D Aqua’s customer-centric approach guarantees a positive experience for clients. Their comprehensive support and maintenance services ensure that clients receive ongoing assistance and value from their STP plants.

Contact Information

For more information about 3D Aqua Water Treatment Company and their STP plant solutions, you can reach them through the following contact details:

- Phone Number: 89630 89630 / 7011143366

- Email: info@3daqua.in

Sewage Treatment Plant (STP) Manufacturer in Delhi Price (1KLD to 500KLD)

Looking for a reliable Sewage Treatment Plant (STP) manufacturer in Delhi? At 3D Aqua, we specialize in designing, manufacturing, and installing compact and efficient STP units ranging from 1 KLD to 500 KLD, suitable for residential societies, hotels, hospitals, industries, and commercial buildings.

Our STP systems use advanced technologies like MBBR, SBR, FAB, and MBR, ensuring effective treatment of domestic and industrial wastewater to meet CPCB norms. Each unit is designed for low footprint, low power consumption, and easy maintenance.

Why Choose 3D Aqua STP:

- Customized capacities from 1 KLD to 500 KLD

- Compact FRP, MS, or RCC-based skid-mounted designs

- Low operating cost with high treatment efficiency

- Odor-free, silent operation with treated water reusable for flushing/gardening

- Fast delivery and installation across Delhi NCR

We offer complete turnkey solutions from design to commissioning, including AMC support.

Price Range (Indicative):

- 1 KLD STP – Starting from ₹1.2 Lakhs

- 5 KLD STP – ₹2.5 to ₹3.5 Lakhs

- 10 KLD STP – ₹4.5 to ₹6.5 Lakhs

- 20 KLD STP – ₹7.5 to ₹10 Lakhs

- 50 KLD STP – ₹12 to ₹18 Lakhs

(Prices may vary based on technology, MOC, and site conditions)

100 KLD STP Plant

- 💧 Treatment Capacity: Effectively treats up to 100,000 liters of sewage per day

- ⚙️ Technology Options: MBBR, SBR, MBR, or ASP based on project needs

- 🌱 Eco-Friendly Output: Produces treated water with BOD <10 mg/L, suitable for reuse

- 🧱 Construction Types: Available in RCC, FRP, or modular skid-mounted units

- 🔌 Energy Efficient: Operates with a power requirement of approx. 7.5–12 kW

- 🛠️ Low Maintenance: Automated operation with minimal manual intervention required

For Quotation Call Us : +91 626262 9090

Contact 3D Aqua today for the best price and a site-specific STP solution tailored to your needs in Delhi NCR.

Conclusion

In the realm of wastewater treatment, 3D Aqua Water Treatment Company stands out as the premier STP plant manufacturer in Delhi. Their commitment to quality, innovative technology, and customer satisfaction make them the best choice for STP solutions in India. By choosing 3D Aqua, you are not only investing in a high-quality product but also contributing to a sustainable and healthier environment. For the best STP plants and unparalleled service, contact 3D Aqua Water Treatment Company today.

FAQs

1. What is a Sewage Treatment Plant (STP)?

A Sewage Treatment Plant (STP) is a facility designed to treat and purify wastewater from residential, commercial, and industrial sources before it is released back into the environment or reused.

2. Why should I choose 3D Aqua for STP plants?

3D Aqua is renowned for its cutting-edge technology, customized solutions, high-quality manufacturing, and exceptional customer service. Their STP plants are designed to meet international standards and ensure 100% satisfaction.

3. What types of STP plants does 3D Aqua manufacture?

3D Aqua manufactures a wide range of STP plants, including residential, commercial, and industrial systems. Each plant is customized to fit the specific needs and scale of the project.

4. How does the STP plant installation process work?

The process includes an initial consultation to understand your needs, design and proposal, manufacturing, installation by skilled technicians, and rigorous testing before commissioning. Ongoing support and maintenance are also provided.

5. What kind of maintenance is required for an STP plant?

Regular maintenance involves checking and cleaning components, monitoring system performance, and ensuring compliance with regulatory standards. 3D Aqua offers comprehensive maintenance services to keep your STP plant in optimal condition.

6. Can STP plants from 3D Aqua handle industrial wastewater?

Yes, 3D Aqua specializes in STP plants designed to handle high volumes and complex pollutants typical of industrial wastewater. Their solutions are tailored to meet industrial requirements and regulatory standards.

7. How do I get in touch with 3D Aqua Water Treatment Company?

You can contact 3D Aqua by phone at 6262629090 or email them at info@3daqua.in for more information or to discuss your STP plant needs.