What Are the Reasons for Leakage in Boiler Tubes? | Causes, Prevention & 3D AQUA Solutions

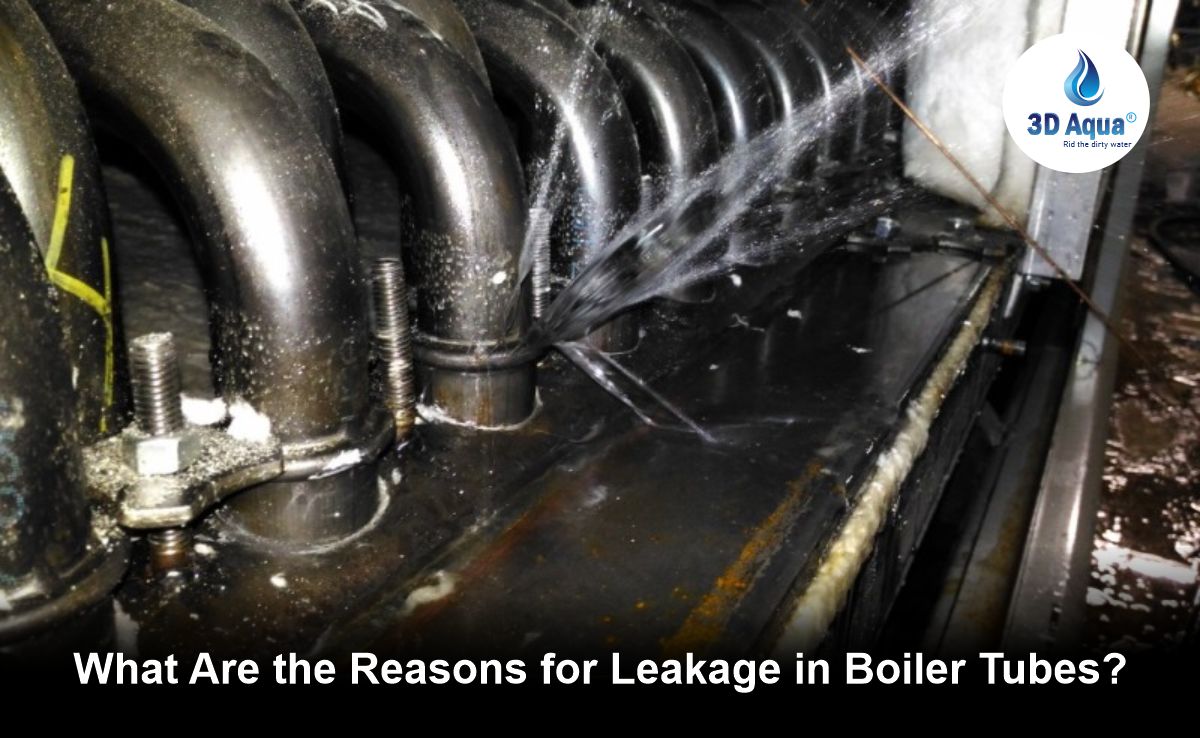

Boiler systems are critical to industrial operations, providing heat and energy for countless processes. However, one of the most common and costly issues plant managers and operators face is boiler tube leakage. Even minor leaks can reduce efficiency, increase downtime, and pose safety hazards. If left unchecked, leakage can lead to catastrophic failures.

In this in-depth article, we explore the main reasons for leakage in boiler tubes, how to prevent them, and why it’s essential to have proper water treatment practices in place. You’ll also discover how 3D AQUA, India’s leading water and wastewater treatment company, offers expert solutions to keep your boiler systems leak-free and fully operational.

🛠️ Understanding the Importance of Boiler Tubes

Boiler tubes are the backbone of heat transfer in a boiler. They are responsible for transferring heat from the combustion chamber to the water, turning it into steam or hot water for industrial use. Because they operate under extreme pressure and temperature, even minor corrosion or scaling can significantly affect performance and cause leakage.

⚠️ Common Causes of Boiler Tube Leakage

Let’s break down the top five reasons for leakage in boiler tubes:

1. 🔩 Tube Corrosion Due to Oxygen Pitting

Corrosion is by far the leading cause of boiler tube leaks. One specific form is oxygen pitting, which occurs when excessive oxygen is present in the boiler feedwater. Here’s how it happens:

- Cold feedwater allows more dissolved oxygen to enter the system.

- When oxygen reacts with iron or steel in the tubes, it forms rust (iron oxide).

- Over time, localized corrosion weakens the metal, forming pits and eventual leaks.

🔧 How to Prevent Oxygen Pitting:

- Preheat the feedwater to reduce dissolved oxygen levels.

- Use chemical oxygen scavengers like sodium sulphite or sodium bisulphite. These bind with free oxygen to form harmless compounds.

- Ensure deaeration equipment is functioning properly.

At 3D AQUA, we provide advanced oxygen scavengers and boiler treatment programs tailored to each boiler’s specifications.

2. ⚙️ Uniform Corrosion Due to Low pH

Another form of corrosion that affects entire boiler units is uniform corrosion, usually caused by low pH levels in the boiler water.

- A pH below 8 creates an acidic environment, accelerating metal degradation.

- Even a small deviation in pH can result in generalized corrosion across all metal surfaces inside the boiler.

- Left untreated, this reduces the lifespan of the boiler and increases maintenance costs.

🧪 Solution:

- Maintain boiler water at a pH of 10 or above.

- Regularly monitor and adjust alkalinity using pH adjusters or buffering agents.

- Implement a water treatment schedule with real-time monitoring.

3D AQUA’s water treatment systems ensure optimal pH balance to prevent this widespread corrosion.

3. 🧱 Boiler Scale Formation

Scale is a hard, crystalline deposit that forms when calcium and magnesium salts precipitate from hard water. It accumulates on tube walls, reducing heat transfer and increasing internal pressure.

- Scale acts as an insulating layer, forcing the system to consume more fuel.

- The increased pressure and temperature can cause boiler tubes to crack or burst.

- Scale also blocks valves and blowdown lines, complicating maintenance.

🔧 How to Prevent Scale Formation:

- Use water softeners to remove hardness-causing minerals.

- Add scale inhibitors that bind with minerals and prevent them from settling.

- Apply BOILER DESCALE solutions to dissolve existing scale.

3D AQUA supplies highly effective descaling and water softening systems engineered for industrial boiler performance.

4. 🌡️ Thermal Shock (Thermodynamic Shock)

Thermal shock occurs when there’s a sudden change in temperature within the boiler system, especially when cold feedwater is introduced into a hot boiler.

- Metal contracts rapidly under cold water, leading to stress fractures in boiler tubes.

- Frequent thermal cycling causes fatigue and eventual cracking.

- Even robust metal alloys can’t withstand abrupt temperature changes.

🔧 Solution:

- Preheat feedwater to 80°C or higher before entering the boiler.

- Avoid starting up cold boilers quickly; instead, bring them up to temperature gradually.

- Use automated control systems to manage temperature consistency.

With 3D AQUA’s automation and monitoring solutions, operators can prevent thermal stress events efficiently.

5. 💧 Improper Boiler Water Treatment Post Installation

Investing in a new boiler is a significant financial decision, but neglecting proper water treatment post-installation is a recipe for disaster.

- Untreated water contains dissolved gases, minerals, and organic contaminants that corrode boiler tubes.

- Rapid scaling and pitting can occur within weeks of operation without a treatment plan.

- The lack of treatment reduces energy efficiency and may void warranties.

🔧 Solution:

- Implement a customized water treatment program from day one.

- Conduct regular water testing and analysis.

- Partner with professionals like 3D AQUA for end-to-end boiler water treatment services.

🧪 Additional Factors That Can Contribute to Boiler Tube Leakage

In addition to the five main causes above, other contributing factors include:

| Factor | Description |

|---|---|

| High TDS (Total Dissolved Solids) | Increases the likelihood of scale formation and corrosion |

| Improper Blowdown Practices | Leads to solid buildup and pressure surges |

| Overloading or Short Cycling | Causes stress on boiler components |

| Incorrect Material Selection | Using non-corrosion-resistant alloys in aggressive environments |

| Contaminated Makeup Water | Introduces bacteria or chemicals into the system |

🔬 Importance of Water Treatment in Boiler Operations

Proper water treatment is the cornerstone of boiler health. It directly affects:

- System longevity

- Thermal efficiency

- Operating costs

- Safety and compliance

Key Water Treatment Processes Include:

- Filtration – Removes suspended solids.

- Softening – Removes hardness-causing minerals.

- Deaeration – Eliminates dissolved oxygen and gases.

- Chemical Conditioning – Adjusts pH, controls corrosion, and prevents scale.

3D AQUA offers turnkey boiler water treatment systems for industrial clients, designed to optimize performance and minimize downtime.

👨🔧 How 3D AQUA Can Help Prevent Boiler Tube Leakages

3D AQUA is a Greater Noida-based leading water and wastewater treatment company trusted by over 500 industrial clients across India and abroad.

🔧 Our Boiler Treatment Solutions:

- Oxygen Scavengers

- Scale Inhibitors

- pH Buffers & Alkalinity Adjusters

- BOILER DESCALE Solutions

- Water Softeners

- Automated Feedwater Systems

- Real-Time Monitoring Equipment

🏆 Why Choose 3D AQUA?

- ✔ ISO, CE, MSME Certified

- ✔ 24×7 Technical Support

- ✔ Serving 1050+ cities in 9 countries

- ✔ Custom Design & On-Site Commissioning

- ✔ Proven Client Satisfaction Record

Whether you need routine maintenance, system design, or chemical dosing support, our expert team has the know-how to keep your boiler system leak-free.

📞 Contact Us

Protect your investment and ensure uninterrupted operation with expert boiler water treatment from 3D AQUA.

📍 3D AQUA – Greater Noida

📞 Call: +91-6262629090

📧 Email: info@3daqua.in

🌐 Website: www.3daqua.in

🧾 Conclusion

Boiler tube leakage is not just a maintenance issue—it’s a symptom of poor system design, inadequate water treatment, or operator oversight. By understanding the primary causes such as corrosion, scaling, and thermal shock, and implementing best practices in water treatment and feedwater management, industries can dramatically increase boiler life, safety, and efficiency.

Let 3D AQUA help you stay ahead of boiler problems with our customized, cutting-edge treatment solutions.