What is ORP in RO Plant and How to Reduce ORP in RO Plant

Reverse Osmosis (RO) plants are widely used across industries, commercial establishments, and even in residential settings for water purification. A lesser-known but highly crucial parameter in RO plant operation is ORP, or Oxidation-Reduction Potential. Understanding ORP is key to maintaining water quality, membrane health, and the overall efficiency of the RO system.

In this article, we will explain what ORP means, why it matters in RO water treatment systems, and how to reduce ORP effectively.

What is ORP in RO Plant?

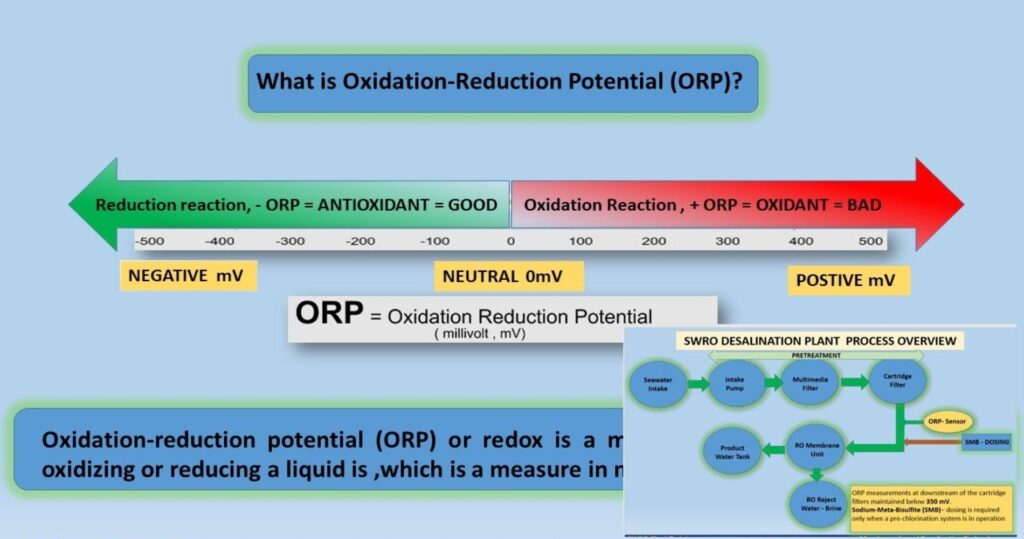

ORP (Oxidation-Reduction Potential) is a measure of a solution’s ability to either release or accept electrons during chemical reactions. It is measured in millivolts (mV) using an ORP sensor or meter. Simply put, ORP tells us whether a water sample is oxidizing or reducing in nature.

Understanding ORP Readings:

- A positive ORP reading means the solution has oxidizing properties. This means it has the potential to remove electrons from other substances. Common oxidizers include chlorine, ozone, and hydrogen peroxide.

- A negative ORP reading indicates reducing properties. It means the water can donate electrons and is more likely to neutralize oxidants.

Typical ORP Ranges in Water Treatment:

- Tap water: +200 mV to +500 mV

- Disinfected water (with chlorine): +600 mV to +800 mV

- RO product water: 0 to +200 mV (ideally low)

- Antioxidant water: -100 mV to -300 mV

In RO plants, high ORP levels can indicate the presence of oxidants, which can degrade RO membranes and affect performance.

Importance of ORP in RO Water Treatment Systems

In an RO system, monitoring ORP is critical for several reasons:

1. Membrane Protection

RO membranes are sensitive to oxidizing agents such as free chlorine, ozone, and hydrogen peroxide. High ORP values generally suggest the presence of these substances, which can cause irreversible membrane damage. Most RO membranes tolerate chlorine levels below 0.1 ppm. Excess chlorine corresponds to high ORP readings and must be removed to protect the membrane.

2. Disinfection Control

ORP is used to monitor and control the effectiveness of chemical disinfection. A certain ORP level (usually around +650 mV) is ideal for killing bacteria and viruses. However, after disinfection, ORP should be reduced before water enters the RO unit.

3. Water Quality Indicator

ORP acts as a real-time indicator of water quality. A low ORP in treated water often means the water is free of harmful oxidants and is safer for downstream processes or consumption.

4. Operational Efficiency

Maintaining optimal ORP levels ensures the long-term performance and lifespan of the RO plant. It also helps avoid unnecessary shutdowns and costly membrane replacements.

Causes of High ORP in RO Plant

Understanding what causes high ORP is essential before attempting to reduce it. Here are some common sources:

1. Chlorination

Most water treatment systems use chlorine or sodium hypochlorite for pre-treatment disinfection. However, if not neutralized properly, residual chlorine reaches the RO membrane, increasing ORP levels significantly.

2. Ozonation

Ozone is a powerful oxidant used for microbial control. Its residuals can elevate ORP beyond safe levels for RO membranes.

3. Hydrogen Peroxide Usage

Sometimes hydrogen peroxide is used for advanced oxidation or biofouling control. It contributes to high ORP if dosed excessively or not decomposed adequately.

4. Poor Dechlorination

If activated carbon filters or dechlorination chemicals are undersized, malfunctioning, or exhausted, chlorine is not removed effectively, leading to a spike in ORP.

How to Reduce ORP in RO Plant

Reducing ORP in an RO plant requires a combination of chemical treatment, physical filtration, and process monitoring. Let’s explore the most effective strategies:

1. Use Activated Carbon Filters

Activated carbon filters are widely used before the RO unit to reduce ORP by adsorbing oxidizing agents like free chlorine, ozone, and other chemicals.

How it works:

- Activated carbon acts as a reducing medium.

- It neutralizes chlorine and other oxidants effectively.

- It also helps in removing organic compounds that can cause membrane fouling.

Best Practices:

- Regularly monitor pressure drop and chlorine breakthrough.

- Replace carbon media periodically based on manufacturer guidelines.

2. Sodium Metabisulfite (SMBS) Dosing

SMBS is a common reducing agent dosed after pre-treatment to neutralize chlorine and reduce ORP.

How it works:

- Reacts with free chlorine and converts it to harmless chloride.

- Lowers ORP to membrane-safe levels.

Dosage:

- Typically 1.8 parts of SMBS are required to neutralize 1 part of chlorine.

- Must be dosed continuously and proportionally with the inlet flow.

Monitoring:

- Check for excess dosing as it can lead to fouling or bio-growth.

- ORP sensors help maintain accurate dosage levels.

3. Monitor and Calibrate ORP Sensors Regularly

ORP meters and sensors must be calibrated and maintained for accurate readings. Drift in sensor performance may lead to incorrect dosing or unsafe operation.

Maintenance Tips:

- Calibrate with standard ORP solutions regularly (e.g., 220 mV, 470 mV).

- Clean electrodes to remove fouling.

- Replace sensors annually or as per manufacturer’s guidelines.

4. Eliminate Excess Ozone and Hydrogen Peroxide

If the plant uses ozone or hydrogen peroxide, make sure the residuals are fully decomposed before entering the RO unit.

Decomposition Methods:

- Catalytic carbon filters for peroxide and ozone.

- UV reactors for hydrogen peroxide degradation.

- Maintain contact time and flow rate for effective oxidation-neutralization.

5. Install Redox Controller Systems

Advanced RO setups now include automated redox control systems that adjust chemical dosing based on real-time ORP feedback.

Benefits:

- Minimizes human error.

- Reduces chemical wastage.

- Ensures consistent ORP levels across all operating conditions.

6. Pre-Treatment Optimization

Ensure that all pre-treatment units are operating optimally:

- Sand filters and micron filters should be cleaned/backwashed regularly.

- Replace filter cartridges as per schedule.

- Ensure proper chlorine contact time and dechlorination reaction zones.

7. Use Antioxidant Additives (if allowed)

In some specialized applications, food-grade antioxidant agents are dosed post-RO to achieve negative ORP for drinking water benefits. This is mainly relevant to alkaline water production systems, not industrial RO plants.

How to Measure ORP in RO Plant

You can measure ORP using:

a) Handheld ORP Meters

Portable and easy to use for quick checks.

b) Online ORP Probes

Installed in pipelines to monitor continuously and provide live feedback to the SCADA or PLC system.

c) Lab ORP Meters

More accurate and useful for calibration and lab-based water quality analysis.

Important Tips:

- Always rinse the sensor before and after use.

- Store sensors properly to avoid electrode drying.

- Compare readings with known ORP standards for accuracy.

Ideal ORP Level for RO Plant Operation

- Pre-RO ORP (after pre-treatment): Below +200 mV

- Post-RO permeate ORP: 0 to +150 mV

- For antioxidant water: Below 0 mV (only in drinking water applications)

A lower ORP near or below 200 mV ensures RO membranes remain safe from oxidative damage.

Common Mistakes in ORP Management

Avoid these common mistakes in ORP control:

- Neglecting ORP sensor calibration

- Overdosing SMBS, which can cause membrane fouling

- Ignoring breakthrough of carbon filters

- Failing to neutralize ozone or peroxide

- Relying only on chlorine test kits instead of ORP meters

Proper training of plant operators is essential for reliable ORP management.

Benefits of Maintaining Proper ORP Levels

- Longer RO membrane life

- Better water quality output

- Reduced chemical consumption

- Fewer system shutdowns

- Compliance with discharge norms

- Reduced operational costs

Conclusion

ORP (Oxidation-Reduction Potential) is a vital yet often overlooked parameter in RO plant operation. High ORP values can cause severe membrane damage due to residual oxidants like chlorine, ozone, and hydrogen peroxide. Fortunately, with proper pre-treatment steps—like using activated carbon filters, SMBS dosing, and real-time ORP monitoring—it’s entirely possible to control and reduce ORP to safe levels.

Whether you’re managing a commercial RO system, an industrial effluent treatment plant (ETP), or a sewage treatment plant (STP) with membrane technologies, maintaining ideal ORP levels ensures efficiency, reliability, and sustainability.