Water pollution is one of the most critical environmental and public health concerns in the modern world. With rapid industrialization, industries such as textiles, pharmaceuticals, food processing, chemicals, and power plants discharge millions of liters of wastewater daily. This wastewater contains toxic chemicals, suspended solids, oils, greases, and pathogens that must be treated before being released into rivers, lakes, or reused within industries.

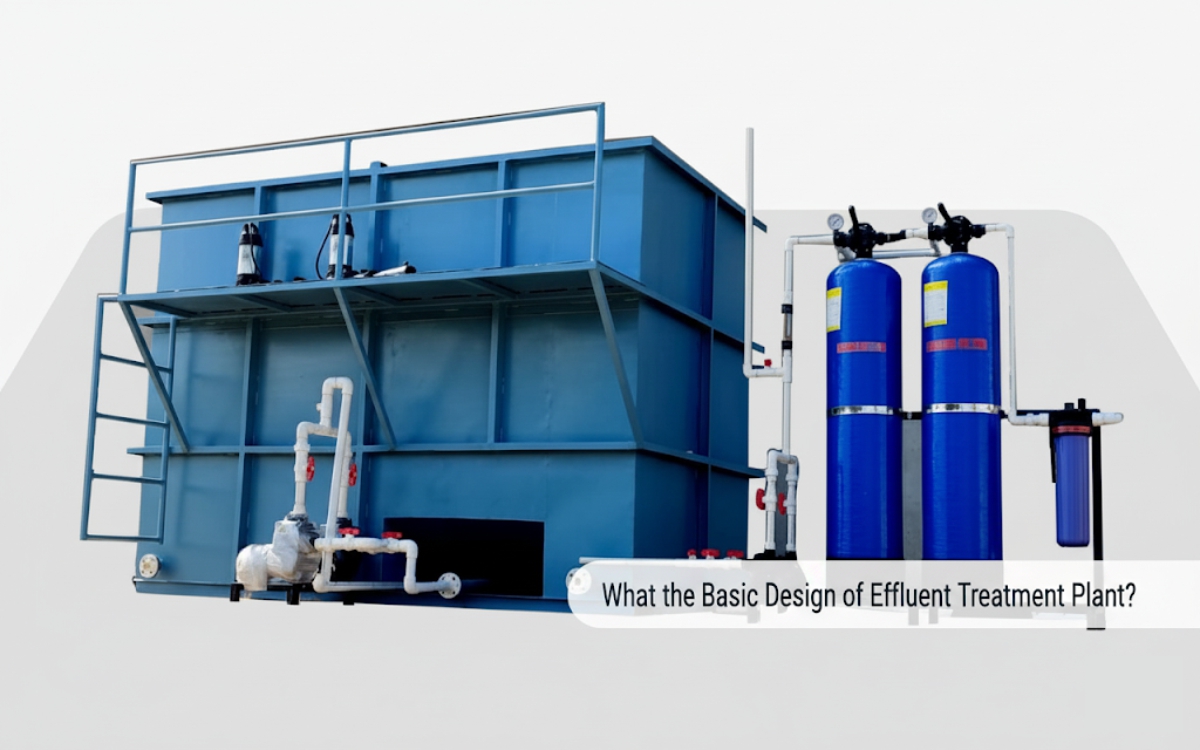

The Effluent Treatment Plant (ETP) is designed to treat this wastewater and make it safe for discharge or reuse. A properly designed ETP not only ensures compliance with environmental regulations but also supports sustainable business practices by minimizing water wastage.

In this article, we will explore in detail the basic design of an effluent treatment plant, covering its essential components, treatment processes, design considerations, and modern approaches for efficiency and sustainability.

Importance of Effluent Treatment Plant Design

Designing an ETP is not just about installing a few tanks and pumps. It requires a scientific approach that considers:

- The nature of wastewater generated.

- Treatment goals and regulatory norms.

- The operational and maintenance requirements.

- Cost-effectiveness and energy efficiency.

- Long-term scalability and sustainability.

When industries understand the basic design of effluent treatment plants, they can build systems that are more efficient, reliable, and compliant with pollution control board standards.

Key Stages in Effluent Treatment Plant Design

The design of an ETP generally follows a step-by-step process, each phase ensuring that the treated water meets quality standards. Let’s look at each stage in detail.

1. Wastewater Characterization

The very first step in ETP design is analyzing the characteristics of wastewater. Every industry produces different types of effluents depending on raw materials and production processes. For example, textile industries discharge dye-rich water, while pharmaceutical plants generate high COD (Chemical Oxygen Demand) effluents.

Key parameters tested include:

- pH – Indicates acidity or alkalinity.

- Biochemical Oxygen Demand (BOD) – Measures biodegradable organic matter.

- Chemical Oxygen Demand (COD) – Reflects total organic pollutants.

- Total Suspended Solids (TSS) – Solid particles present in water.

- Oil and Grease – Common in food processing and mechanical industries.

- Heavy Metals – Lead, chromium, mercury, etc. from electroplating and chemical industries.

- Nutrients – Nitrogen and phosphorus, which cause eutrophication.

Without proper characterization, the treatment process may fail to achieve desired results.

2. Defining Treatment Goals and Ensuring Regulatory Compliance

Every ETP is designed to meet specific treatment goals, which usually align with:

- Central Pollution Control Board (CPCB) or State Pollution Control Board (SPCB) norms.

- Local discharge limits for industries.

- Zero Liquid Discharge (ZLD) policies in some regions.

Common treatment objectives include:

- Reducing BOD and COD to permissible levels.

- Removing suspended solids and turbidity.

- Neutralizing extreme pH levels.

- Eliminating pathogens through disinfection.

- Recovering and recycling water for reuse.

Compliance ensures industries avoid legal penalties while contributing to a cleaner environment.

3. Flow Rate and Capacity Planning

An ETP must be designed to handle the actual volume of wastewater generated by the industry. Designers calculate:

- Daily average flow rate (normal operation).

- Peak flow rates during high production.

- Seasonal variations in water usage.

- Future expansion needs of the industry.

Accurate flow estimation ensures that tanks, pumps, and equipment are not undersized (causing overload) or oversized (leading to wastage of resources).

4. Selection of Treatment Processes

The heart of any ETP lies in the treatment process design. Based on wastewater quality, the system includes:

a) Primary Treatment

- Screening: Removal of plastics, rags, and large solids.

- Equalization tank: Balances flow and pollutant concentration.

- Oil and grease trap: Skims out floating oils.

- Primary clarifier: Settles heavy particles.

b) Secondary Treatment (Biological Treatment)

- Activated Sludge Process (ASP): Uses microbes to degrade organic matter.

- Moving Bed Biofilm Reactor (MBBR): Carries biofilm on carriers for efficient treatment.

- Sequencing Batch Reactor (SBR): Batch process with aeration and settling in the same tank.

- Anaerobic Digesters: Ideal for high-strength wastewater, generating biogas as byproduct.

c) Tertiary / Advanced Treatment

- Filtration (sand, carbon, or membrane-based).

- Disinfection (UV, ozone, or chlorine).

- Reverse Osmosis (RO): For high-purity water recovery.

- Advanced Oxidation Processes (AOPs): For difficult-to-degrade pollutants.

d) Sludge Treatment

- Thickening & Dewatering: Reduces water content.

- Drying beds or mechanical presses: For disposal.

- Biogas recovery: Converts sludge into energy.

5. Equipment Selection and Sizing

To achieve desired performance, ETP equipment must be carefully selected and sized. Important components include:

- Pumps, pipelines, and valves.

- Aerators and blowers.

- Clarifiers and settlers.

- Dosing systems for chemicals.

- Filtration units (sand, carbon, membrane).

- Sludge handling equipment.

Each piece of equipment is designed based on flow rates, treatment goals, and industry requirements.

6. Layout and Space Planning

An ETP should have a logical and compact layout that minimizes pumping needs while ensuring easy maintenance. Designers must consider:

- Smooth process flow from one stage to another.

- Safety and accessibility for operators.

- Odor control and ventilation.

- Space for future expansion.

A poorly planned layout often leads to higher operating costs and inefficiency.

7. Instrumentation and Automation

Modern ETPs are equipped with advanced monitoring and control systems:

- Online sensors for pH, DO, turbidity, and COD.

- PLC (Programmable Logic Controller) for automation.

- SCADA (Supervisory Control and Data Acquisition) for centralized monitoring.

- Automated chemical dosing systems.

- Remote monitoring for real-time adjustments.

Automation reduces human errors, improves reliability, and lowers operational costs.

8. Energy Efficiency Considerations

Since aeration and pumping consume maximum energy, designers must adopt energy-saving strategies, such as:

- High-efficiency pumps and blowers.

- Variable Frequency Drives (VFDs).

- Optimized aeration systems.

- Solar-powered ETP components.

- Biogas recovery from anaerobic digesters.

Energy-efficient ETPs help industries save costs while meeting sustainability targets.

9. Chemical Optimization

Chemicals like coagulants, flocculants, and disinfectants are widely used in ETPs. However, overuse increases cost and environmental impact. Best practices include:

- Accurate dosing systems.

- Alternative eco-friendly chemicals.

- Recovery and reuse of certain chemicals.

- Advanced treatment methods that reduce chemical dependency.

10. Odor Control

Industrial wastewater often produces foul odors that disturb nearby communities. Effective odor control measures include:

- Covered tanks and enclosed treatment units.

- Biofilters and activated carbon filters.

- Chemical scrubbers.

- Proper ventilation and housekeeping.

11. Safety and Environmental Protection

An ETP must be designed with safety measures for workers and surrounding areas:

- Spill containment systems.

- Safe access platforms and railings.

- Emergency shutdown systems.

- Noise reduction measures.

- Adequate lighting and ventilation.

12. Operation and Maintenance Planning

The long-term success of an ETP depends on ease of operation and maintenance. Key design considerations include:

- Clear operational manuals.

- Scheduled maintenance programs.

- Spare parts inventory.

- Accessible sampling and testing points.

- Redundancy in critical equipment.

13. Cost Optimization

Industries are always concerned about ETP cost-effectiveness. Strategies include:

- Life cycle cost analysis before design finalization.

- Resource recovery (water reuse, energy recovery).

- Modular and phased expansion.

- Exploring third-party treatment services.

14. Flexibility and Scalability

Since industries expand and regulations evolve, ETPs must be designed to handle:

- Increased wastewater load.

- New pollutant types.

- Stricter environmental norms.

- Upgraded treatment technologies.

A scalable design ensures long-term viability.

15. Pilot Testing and Validation

Before commissioning a full-scale ETP, industries often run pilot plants. This helps in:

- Validating selected treatment processes.

- Fine-tuning chemical doses and parameters.

- Identifying operational challenges.

- Collecting real-time data for optimization.

Pilot testing reduces risks and improves efficiency of the main plant.

Conclusion

The basic design of an effluent treatment plant (ETP) involves more than just tanks and pipelines. It is a comprehensive approach that integrates wastewater characterization, regulatory compliance, process selection, equipment design, automation, energy efficiency, and long-term sustainability.

A well-designed ETP ensures:

- Protection of water bodies and the environment.

- Compliance with pollution control regulations.

- Cost-effective and efficient wastewater treatment.

- Opportunities for water reuse and resource recovery.

If you are planning to set up or upgrade an ETP for your industry, professional expertise is essential.

Partner with 3D AQUA – India’s Leading ETP Manufacturer

At 3D AQUA Water Treatment Company, we specialize in designing and manufacturing advanced ETPs tailored to industry-specific needs. With decades of experience, modern infrastructure, and global exports, we provide cost-effective, energy-efficient, and regulatory-compliant wastewater treatment solutions.

📞 Contact Us Today:

- Phone: +91-6262629090

- Email: info@3daqua.in

Let our experts help you design a sustainable and future-ready effluent treatment plant.