Water quality is an increasingly critical concern in our rapidly industrializing world. Ultrafiltration (UF) has emerged as a vital water purification method, offering an effective solution to meet the stringent demands for clean, safe water across various sectors. This article delves into the intricacies of ultrafiltration, its mechanisms, applications, advantages, and the market trends shaping its future.

What is Ultrafiltration (UF) In Water Treatment?

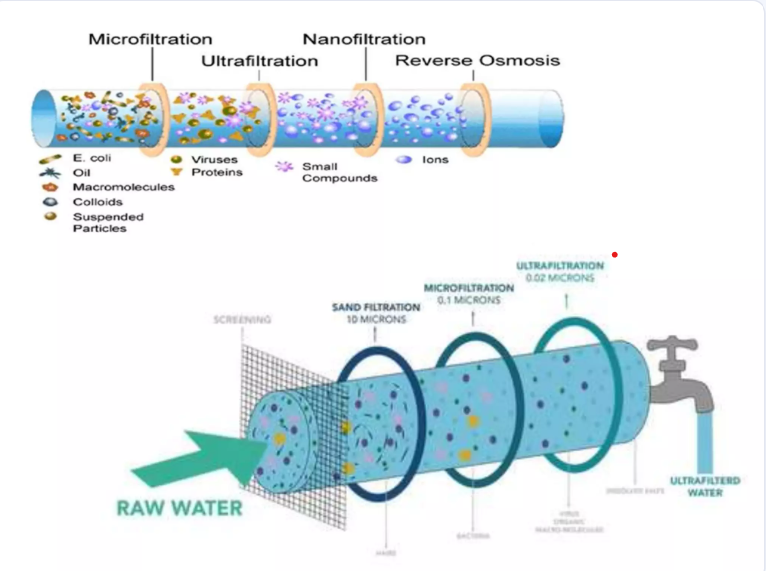

Ultrafiltration is a membrane-based filtration process that separates particles from liquids at the molecular level. It operates using semipermeable membranes with pore sizes typically ranging from 0.1 to 0.01 microns. This technology effectively removes suspended solids, colloids, bacteria, and larger organic molecules, while allowing water and low-molecular-weight solutes to pass through.

The Mechanism of Ultrafiltration

At its core, ultrafiltration utilizes the principle of size exclusion. When water is pushed through the membrane, particles larger than the membrane’s pore size cannot pass through, resulting in two distinct streams:

- Permeate: The filtered water that passes through the membrane.

- Retentate: The concentrated stream containing larger particles that are unable to cross the membrane.

This separation process is critical for various applications, from municipal water treatment to industrial wastewater management.

Types of Ultrafiltration Membranes

The performance of an ultrafiltration system is heavily influenced by the type of membrane used. Each membrane type has its unique properties and applications:

1. Tubular Membranes

Description: Tubular membranes consist of a series of long, hollow tubes made from various materials, often PVC or stainless steel.

Advantages:

- Easy to clean and maintain due to their larger diameter.

- Resistant to fouling, making them suitable for high-solid-content applications.

Applications: Commonly used in wastewater treatment, especially in membrane bioreactors and oily wastewater treatment.

2. Hollow Fiber Membranes

Description: These membranes consist of fine, hollow fibers, offering a high surface area and packing density.

Advantages:

- Flexibility in design and operation.

- Lower feed pressure requirements and excellent performance in high total dissolved solids (TDS) environments.

Applications: Ideal for municipal drinking water, beverage processing, and various industrial applications.

3. Spiral-Wound Membranes

Description: Made by rolling layers of membrane material around a perforated central tube.

Advantages:

- High throughput due to the larger surface area.

- Cost-effective and easy to clean.

Applications: Used in applications such as protein concentration, dye desalting, and wastewater treatment.

4. Plate and Frame Membranes

Description: These modules consist of flat membranes sandwiched between support frames, allowing for flexible configurations.

Advantages:

- Good fouling resistance and easy scalability.

- Can handle high concentrations of solids efficiently.

Applications: Commonly found in cosmetics production, food and beverage processing, and wastewater reuse.

Read Also: Water Ultrafiltration Manufacturers in Delhi NCR

Ultrafiltration Operating Principles

The Process Flow

Ultrafiltration can operate using two main configurations: dead-end filtration and cross-flow filtration.

Dead-End Filtration

In this method, the feed stream flows perpendicular to the membrane surface. Particles accumulate on the membrane, forming a filter cake. This approach typically offers high recovery rates but requires frequent cleaning due to the buildup of contaminants.

- Use Cases: Ideal for batch processes or systems with low concentrations of particulates, such as laboratory applications.

Cross-Flow Filtration

Here, the feed stream flows parallel to the membrane surface. This design minimizes the accumulation of solids, allowing for continuous operation and reducing the need for cleaning. The system produces two streams: permeate and retentate, with the latter often recirculated to maintain concentration.

- Use Cases: Well-suited for industrial applications with high solid content, such as food processing and wastewater treatment.

Read Also: Best UF RO Plant: Ultrafiltration System and UF Membrane Manufacturer and Suppliers

Key Advantages of Ultrafiltration

Ultrafiltration offers numerous benefits, making it a popular choice for water treatment across various industries.

1. High Efficiency and Effectiveness

UF membranes can achieve up to 90-100% removal of pathogens and contaminants, ensuring high-quality water suitable for drinking and industrial applications. This efficiency is crucial in sectors requiring stringent compliance with health and safety regulations.

2. Compact Design

Compared to traditional filtration methods, ultrafiltration systems occupy significantly less space. This compactness allows for easy integration into existing infrastructure, especially in urban areas where space is at a premium.

3. Chemical-Free Operation

Ultrafiltration generally operates without the need for chemical additives, aside from those required for cleaning the membranes. This attribute not only reduces operational costs but also minimizes environmental impact.

4. Low Operating Costs

With advancements in membrane technology and manufacturing, UF systems have become more cost-effective. Their low energy requirements and minimal maintenance needs contribute to reduced overall operating expenses.

5. Versatile Applications

Ultrafiltration is applicable in various industries, including:

- Municipal Water Treatment: Providing safe drinking water by removing contaminants and pathogens.

- Wastewater Treatment: Enhancing effluent quality for reuse and compliance with environmental regulations.

- Food and Beverage Processing: Ensuring product quality by removing impurities and extending shelf life.

- Pharmaceuticals: Guaranteeing the purity of water used in drug manufacturing processes.

Market Trends and Future Outlook

The ultrafiltration market is experiencing significant growth driven by several factors:

Rising Water Pollution

As industrial activities increase, so do the levels of water contamination. This situation necessitates advanced filtration systems capable of treating polluted water effectively.

Regulatory Compliance

Stricter regulations regarding water quality and wastewater discharge are compelling industries to adopt ultrafiltration systems. Compliance with these regulations is crucial for maintaining operational licenses and avoiding penalties.

Sustainability Initiatives

With a growing focus on sustainability, many companies are looking for ways to recycle and reuse water. Ultrafiltration plays a vital role in these efforts, providing a means to treat wastewater for safe reuse.

Technological Advancements

Innovations in membrane technology, including improved materials and designs, are enhancing the efficiency and affordability of ultrafiltration systems. These advancements are making UF more accessible to a wider range of industries.

Leading Ultrafiltration Manufacturers

In the global ultrafiltration market, several companies are at the forefront of innovation and quality. One prominent manufacturer is 3D Aqua Water Treatment Company, based in India.

Read Also: Best Ultrafiltration Water System Manufacturers in India

Why Choose 3D Aqua?

- Customized Solutions: 3D Aqua specializes in designing ultrafiltration systems tailored to the unique needs of various industries, including textiles, food processing, and pharmaceuticals.

- Quality Assurance: The company adheres to international standards, ensuring that every system is rigorously tested for performance and durability.

- Comprehensive Support: 3D Aqua offers exceptional customer service, including lifetime support and regular maintenance checks to ensure optimal performance of their systems.

- Extensive Market Reach: With operations across major industrial hubs in India, including Delhi NCR, Maharashtra, Gujarat, and Karnataka, 3D Aqua is well-positioned to serve a diverse client base.

Case Studies of Success

- Textile Industry: A leading textile manufacturer in Gujarat implemented a 3D Aqua ultrafiltration system, resulting in reduced water consumption and improved product quality.

- Food Processing: An industrial food processing unit in Maharashtra adopted 3D Aqua’s sewage treatment plant, enhancing wastewater management and regulatory compliance, leading to operational efficiency.

- Pharmaceuticals: A major pharmaceutical company in Bengaluru relied on 3D Aqua’s ultrafiltration systems to ensure the purity of water used in drug manufacturing, meeting stringent regulatory requirements while minimizing waste.

Conclusion

As global concerns about water quality continue to grow, ultrafiltration technology stands out as an effective solution for providing clean, safe water. Its high efficiency, compact design, and versatile applications make it a preferred choice for industries ranging from municipal water treatment to pharmaceuticals.

With leaders like 3D Aqua Water Treatment Company paving the way, the future of ultrafiltration looks promising. Their commitment to quality, customer satisfaction, and continuous innovation positions them as a trusted partner in addressing the world’s water challenges.

For more information on ultrafiltration systems and to explore customized solutions tailored to your needs, contact 3D Aqua at 89630 89630 or visit their website at www.3daqua.in. Their expert team is ready to assist you in achieving optimal water treatment solutions for your specific requirements.