Reverse osmosis (RO) membranes play a crucial role in industrial water treatment systems. These membranes are responsible for removing impurities and ensuring clean, purified water for various applications.

The quality and durability of membranes directly impact the efficiency and operational costs of an RO plant. Industries seek membranes that provide longevity, high performance, and minimal maintenance to maximize cost-effectiveness.

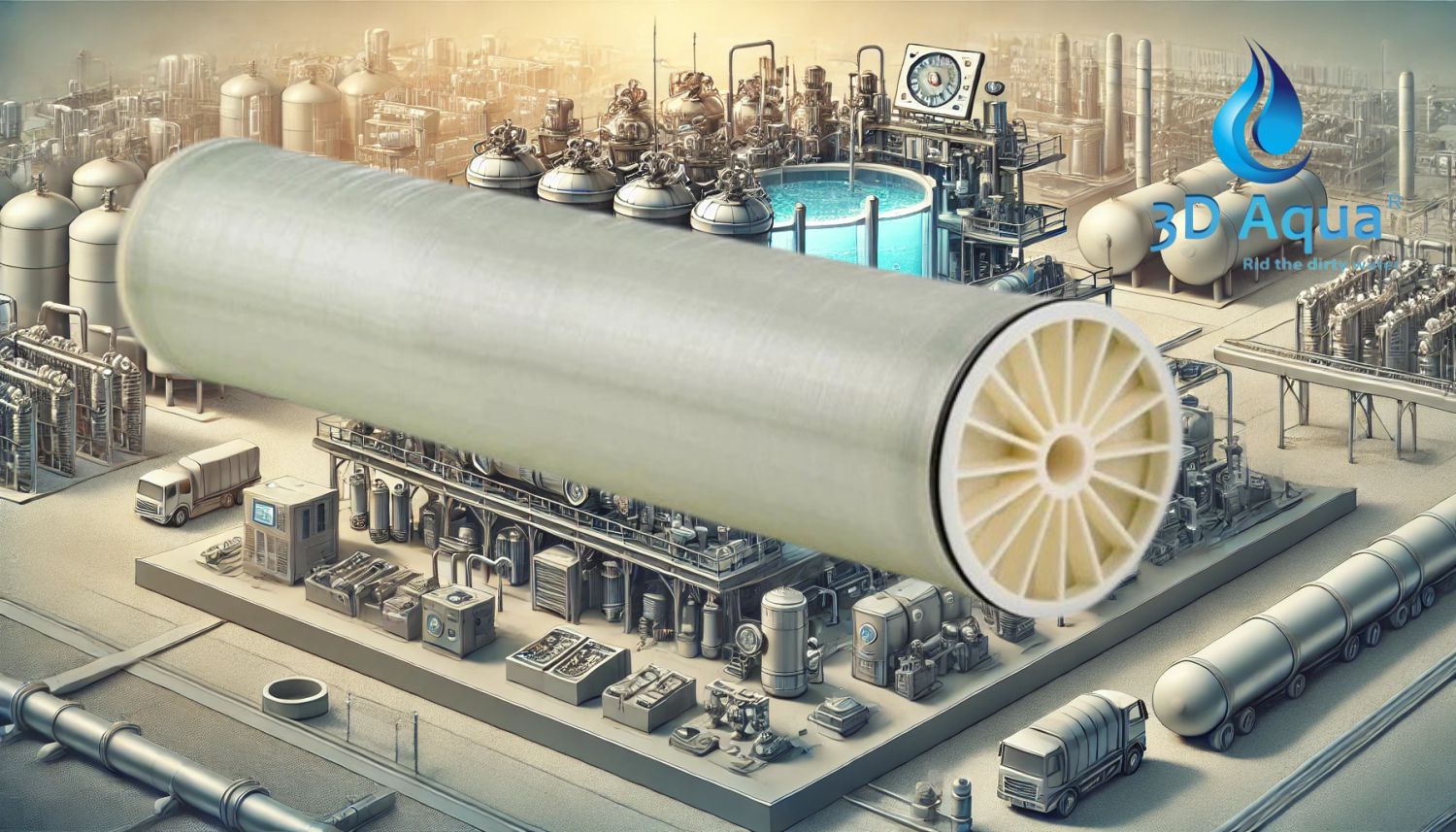

At 3D Aqua Water Treatment Company, we specialize in manufacturing high-quality RO membranes and complete water treatment solutions. Our products are designed for long-term durability and efficiency, making us a trusted name in industrial RO plant manufacturing. Choosing the right membranes can significantly reduce downtime, enhance productivity, and improve overall plant performance.

Understanding RO Membranes

RO membranes serve as the core component of the water filtration process. They function through a semi-permeable barrier that allows water molecules to pass while blocking contaminants such as salts, minerals, bacteria, and heavy metals. Among the different types of RO membranes, Thin Film Composite (TFC) membranes are the most widely used in industrial applications due to their durability and efficiency.

Types of Industrial RO Membranes:

- Thin Film Composite (TFC) Membranes – High rejection rate and long lifespan with proper maintenance.

- Cellulose Acetate (CA) Membranes – Lower resistance to biological fouling but cost-effective.

- High-Pressure RO Membranes – Suitable for desalination and treating high-TDS water.

- Low-Pressure RO Membranes – Energy-efficient and effective for moderately contaminated water sources.

Proper selection of membranes is essential for ensuring an industrial RO plant operates smoothly with minimal energy consumption and maintenance requirements. At 3D Aqua Water Treatment Company, we provide expert guidance in choosing the right membranes based on water quality and plant needs.

Key Factors That Affect Membrane Lifespan

Several factors influence the longevity of RO membranes in industrial settings. Understanding and managing these factors can help extend membrane life and maintain plant efficiency.

1. Feed Water Quality

The composition of feed water plays a crucial role in determining how long membranes last. High levels of contaminants such as hardness, iron, silica, and organic matter can lead to scaling and fouling, reducing membrane efficiency. Pretreatment methods such as filtration, softening, and chemical dosing can help maintain membrane integrity.

2. Operating Pressure

Industrial RO plants require optimal pressure to push water through the membranes. Excessive pressure can damage membranes and reduce their lifespan, while insufficient pressure may lead to poor filtration. Regular monitoring of pressure levels ensures consistent performance.

3. Chemical Cleaning and Maintenance

Membranes require periodic cleaning to remove accumulated contaminants. Using the right cleaning agents and following recommended procedures can prevent irreversible membrane damage. Harsh chemicals, if not used correctly, may weaken the membrane material and shorten its lifespan.

4. Temperature and pH Levels

Extreme temperatures and pH fluctuations can degrade membrane materials over time. Maintaining the recommended temperature and pH range ensures the longevity of membranes and prevents premature wear and tear.

5. Proper System Design

An industrial RO plant designed with appropriate pre-filtration, pressure regulation, and monitoring systems will enhance membrane life. Poor system design leads to unnecessary strain on membranes, increasing the need for replacements.

At 3D Aqua Water Treatment Company, we integrate advanced design strategies to maximize membrane efficiency and lifespan, helping industries achieve reliable water treatment solutions.

Best Practices for Membrane Maintenance

Maintaining RO membranes properly extends their life and ensures consistent water quality. Below are essential maintenance practices:

- Routine Monitoring: Regularly check pressure, flow rates, and rejection rates to detect early signs of membrane fouling or scaling.

- Scheduled Cleaning: Follow a structured cleaning schedule using industry-recommended cleaning agents to prevent buildup.

- Proper Pre-Treatment: Implement necessary pre-treatment methods such as filtration, softening, and anti-scalant dosing to protect membranes.

- Avoid Sudden Operational Changes: Gradual startup and shutdown processes prevent membrane stress and potential damage.

- Record-Keeping: Maintain logs of membrane performance, cleaning cycles, and replacement dates to track efficiency trends.

3D Aqua Water Treatment Company provides detailed maintenance guidelines and technical support to ensure smooth plant operations and prolonged membrane life.

Choosing the Right Industrial RO Plant Manufacturer

Selecting a reliable manufacturer is just as important as choosing high-quality membranes. A well-established manufacturer ensures durability, efficiency, and long-term support. 3D Aqua Water Treatment Company stands out as a leader in industrial RO plant manufacturing, offering top-tier products and services tailored to various industries.

Why Choose 3D Aqua?

✔ High-Quality Membranes: Engineered for longevity and superior performance.

✔ Advanced RO System Design: Customized solutions for diverse industrial needs.

✔ Comprehensive Maintenance Support: Expert guidance and service assistance.

✔ Energy-Efficient Technology: Reducing operational costs and enhancing sustainability.

✔ Trusted by Leading Industries: Proven track record in delivering high-quality RO plants.

By partnering with 3D Aqua Water Treatment Company, industries benefit from top-quality membranes and expert assistance, ensuring their water treatment systems operate at peak efficiency.

Conclusion

The lifespan of RO membranes in industrial plants depends on several factors, including feed water quality, operating conditions, maintenance practices, and system design. Understanding and managing these factors ensures longer-lasting membranes, reduced operational costs, and enhanced efficiency.

As a leading industrial RO plant manufacturer, 3D Aqua Water Treatment Company provides high-quality membranes, expert guidance, and reliable maintenance solutions. By selecting the right membranes and implementing proper care, industries can optimize their water treatment systems and achieve long-term success.

Contact 3D Aqua Water Treatment Company

For premium industrial RO membranes and customized water treatment solutions, reach out to us today:

📍 Office Address: 3D Aqua Water Treatment Company, [Your Location]

📞 Phone: +91 6262629090

📧 Email: info@3daqua.com

🌐 Website: www.3daqua.com

Let 3D Aqua Water Treatment Company help you enhance your RO plant’s efficiency with long-lasting, high-quality membranes!